In a world where markets and industries are in a constant state of flux, it becomes imperative to rely on the tried and tested originals when selecting technology providers and partners to guide you through the ever-evolving landscape.

At this year’s China Glass exhibition, we are thrilled to present a glimpse into some of our latest technological advancements. Here are a few of the groundbreaking innovations that you can anticipate experiencing firsthand:

**Insulating Glass Manufacturing:**

*TPS® – Revolutionizing IG Manufacturing*

Exclusively available in China through Glaston COMFORT IG lines, TPS® stands as the epitome of modernity, flexibility, and efficiency in producing insulating glass units and multilayer solar panels. By directly applying Thermo Plastic Spacer material onto the glass plate, TPS® streamlines production processes significantly. This eliminates the necessity to stock various spacer profiles and connectors, while enabling changes to spacer width during the process without any loss of time.

Developed by Glaston, TPS® has been installed in over 170 glass processing facilities globally. The technology, originating from Germany, incorporates key components like TPS®’APPLICATOR and UNIT’ASSEMBLER, which are sourced from Germany. Paired with other line components manufactured and assembled in China, the new COMFORT line featuring TPS® capabilities serves as the ideal entry point into TPS® IG manufacturing technology for Chinese customers.

*Glaston COMFORT’SEALER – Automating Sealing Processes*

For those seeking to move away from manual sealing of IG units, the automatic sealing robot COMFORT’SEALER transforms Glaston COMFORT BOX into a fully automated insulating glass production line. Boasting high material dosing accuracy through gear pump dosing technology, COMFORT’SEALER precisely determines sealing depth and width, applying the exact volume of sealing material required.

**Flat Glass Tempering:**

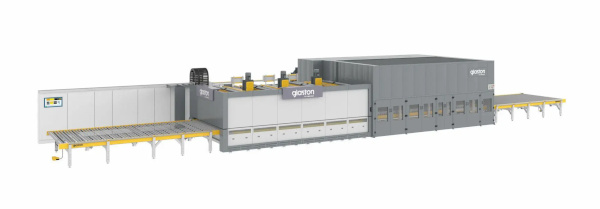

Glaston TC Series – Energy-Efficient Production

Efficient and precise heating is vital for high-yield, high-performance glass production. The TC Series tempering furnace incorporates the Chinook circulated air convection system, minimizing energy consumption to the bare minimum. This system ensures faster heat transfer for shorter cycle times, reducing overall production costs, including labor costs per square meter.

*Glaston RC Series – Effortless Processing for Various Glass Types*

From shower doors to architectural glass, the Glaston RC Series guarantees effortless tempering for all glass types. With an accurate and intelligent heating system, the RC Series maintains impeccable glass quality even at increased production rates. It offers the highest uptime, can be easily upgraded to meet evolving processing needs, and ensures easy maintenance, along with the best availability of spares and support in the market.

**Automotive Glass Processing:**

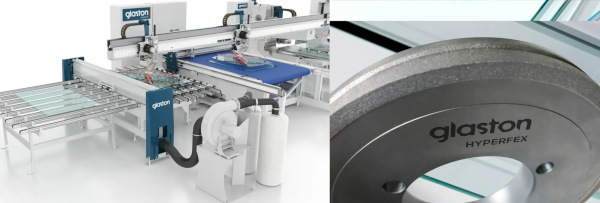

*Glaston CHAMP EVO – Evolution in Automotive Glass Preprocessing*

Representing the latest evolution in the CHAMP automotive glass pre-processing line, Glaston CHAMP EVO features a grinding machine with significantly enhanced precision. Its energy-saving linear drives reduce maintenance costs and wear, marking a significant leap forward in automotive glass preprocessing technology.

Meet us at China Glass 2024, Hall N1, Booth #300!

GLASTON TIANJIN OPEN HOUSE – EXPERIENCE INNOVATION FIRSTHAND

We invite you to visit our state-of-the-art facilities and take a closer look at Glaston glass processing technology in action!

Explore our COMFORT IG line demo, see the TC Series tempering line in assembly and witness the precision of our CHAMP EVO pre-processing line.

Date: Monday, April 29, 2024, from 10:00-15:00

Venue: Glaston Tianjin (close to Beijing),

Register: [email protected]

Source:Glaston Corporation with additional information added by GlassBalkan