The laminated glass market continues to grow, driven by demands for enhanced safety, security, and acoustic performance in architectural and automotive applications.

Within this dynamic sector, CMS Glass Technology has firmly established itself as a key player, consistently demonstrating its commitment to innovation and the development of cutting-edge solutions. Recent advancements solidify their position as a leader, particularly in addressing the complexities of laminated glass processing.

For years, laminated glass cutting presented significant challenges to fabricators. The inherent composition of this material – multiple layers of glass bonded by interlayers – demands specialized techniques to achieve clean, precise cuts without delamination or other defects. These challenges directly impact production efficiency, material waste, and overall quality. CMS Glass Technology has directly tackled these issues, investing heavily in research and development to deliver technologies that are not only effective but also remarkably efficient.

Solutions for laminated safety glass

CMS Glass Technology has introduced an advanced solution for cutting laminated safety or fire-resistant glass: CMS sprint, designed to optimize productivity in laminated, fire and safety glass processing lines, offering high performance and precision in all phases of the process.

Cutting complex geometries

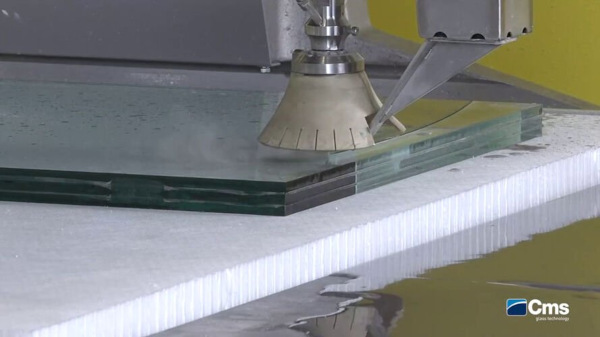

To meet the cutting needs of laminated glass with non-linear and complex shapes, CMS Glass Technology offers waterjet technology, a solution that provides precision, versatility and reliability, perfect for the most demanding projects.

New concept for conventional laminated glass

At Glasstec 2024, CMS presented the new cutting table concept, agil lam, designed to optimize the cutting of conventional laminated glass. The new solution stands out for its precision, speed and ease of use.

Thanks to increasingly advanced, precise and versatile machines, CMS Glass Technology is ready to continue to innovate the laminated glass processing and cutting sector.

Source: CMS Glass Technology with additional information added by GlassBalkan