Optimize Your Glassworks: The Advantage of Integrated Lines with Grinding and Washing Machines

Glass production has entered a new era of efficiency with the integration of grinding machines and washing machines in glassworks. The inclusion of both grinders and washing machines in an integrated line proves to be a game-changer for any glass production line. Immediately following the grinding operation, the glass washing process becomes crucial to eliminate residues and prevent surface scratching from glass debris.

In the realm of glass processing, the washing machine emerges as an indispensable component, ensuring thorough cleaning of all glass sheets before further intervention. Opting for an integrated line simplifies the entire process, guaranteeing that your glassworks delivers top-quality glass sheets with minimal effort.

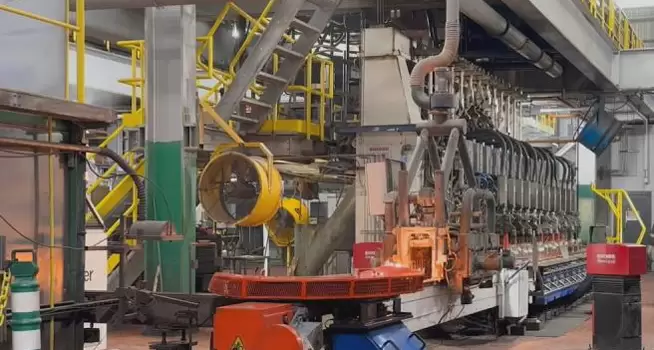

Introducing an integrated line to your glassworks, encompassing both a glass grinding machine and a vertical washing machine, presents a tremendous opportunity. The primary advantage lies in seamlessly transitioning the glass sheet from the grinding process to the washing phase, ensuring efficient management of all aspects of glass processing and cleaning under a single entity—the glassworks. This immediate washing process, as opposed to storing glasses on a trolley awaiting washing, prevents debris from drying on the glass surface, particularly in hot, dry environments. The integration of edging and washing machines not only ensures precision and speed in production but also reduces time and costs significantly.

With over 15 years of expertise, Lattuada has been at the forefront of studying and creating innovative solutions for glass washing. We aim to provide effective and efficient responses to our customers’ needs for washing glasses post the grinding process. Our range of vertical washing machines, distinguished by high technology, user-friendliness, and easy maintenance, seamlessly integrates with production lines, ensuring exceptional performance and high productivity.

At Lattuada, washing machines, designed to complement grinding solutions, can easily integrate with other machines such as vertical grinding, drilling, milling lines, and CNC machines. Our vertical washing lines, available in open top (OT line) or closed top (CT), vary in useful washing height, number of brushes, and total loadable weights. Constructed with stainless steel and materials in contact with water, machines prioritize longevity and minimize maintenance costs.

Source: Adelio Lattuada Srl with additional information added by GlassBalkan