In a significant stride towards sustainable manufacturing, Verallia, the world’s third largest glass packaging producer, and Fives, a prominent engineering group, forged a strategic partnership in 2022.

This collaboration has culminated in the creation of a groundbreaking all-electric furnace, a pivotal development for the glass manufacturing sector aimed at drastically reducing carbon emissions.

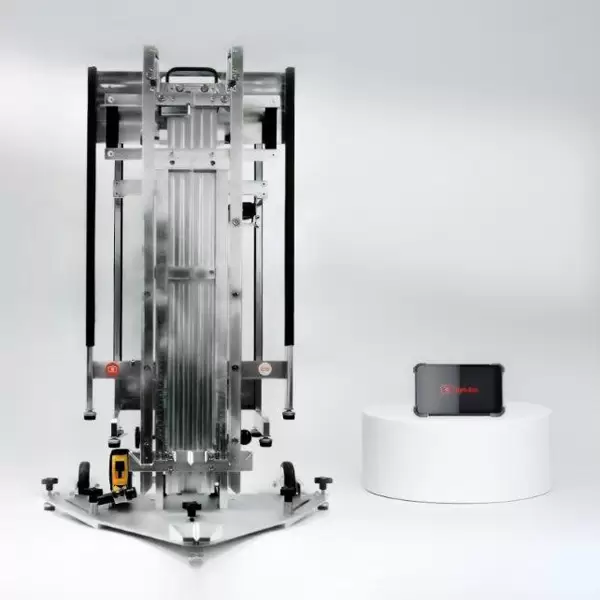

Officially inaugurated on September 10, 2024, at Verallia’s facility in Cognac, France, the new furnace leverages the Prium® E-Melt technology developed by Fives. This innovative furnace represents a remarkable advancement in the production of both flint and extra-flint glass, designed specifically to accommodate the needs of flagship Cognac brands. With a production capacity of 180 tonnes of glass per day—equivalent to an astonishing 300,000 bottles—the Prium® E-Melt is hailed as the largest electric furnace in the glass packaging industry globally.

A Step Forward in Carbon Reduction

The environmental benefits of this new furnace are substantial. It is projected to reduce CO2 emissions by up to 60 percent, releasing only between 12,000 and 14,000 tonnes of CO2 annually—significantly lower than the 30,000 tonnes emitted by traditional gas furnaces. Not only does the Prium® E-Melt furnace contribute to a marked reduction in carbon footprint, but it also enhances energy efficiency, with approximately 95 percent of the energy utilized directly in the glass production process. This initiative received backing from ADEME, the French Agency for Ecological Transition, as part of the ‘France 2030’ investment plan, signifying its importance in the broader context of ecological progress.

A Game-Changing Collaboration

Patrice Lucas, CEO of the Verallia Group, expressed pride in the company’s pioneering role within this endeavor, stating, “It’s our 100 percent electric furnace, fully illustrating our CSR roadmap and ambitious investment plan to optimize energy consumption at our sites and develop low-carbon furnaces.” This development not only underscores Verallia’s commitment to sustainable practices but also marks a significant shift in industry standards for electric melting processes.

Guillaume Mehlman, President of Steel & Glass at Fives, echoed this sentiment, emphasizing the strategic importance of the partnership: “This is a strategic project for both Verallia and Fives as leaders in low carbon glass making technology. Our technology will be a game-changer for the industry as it enables the highest glass quality with the lowest energy input and minimum carbon emissions.”

Looking Ahead

The inauguration of the Prium® E-Melt furnace in Cognac signals a crucial advancement in the ongoing quest for decarbonization within the glass manufacturing sector. Both Verallia and Fives are committed to sustainable operations and continual innovation in their manufacturing processes. As the industry pivots towards greener practices, this collaboration sets a precedent for integrating advanced technologies that prioritize both quality and environmental responsibility.

As we look ahead, the efforts made by Verallia and Fives not only contribute to immediate sustainability goals but also serve as a beacon for future developments in environmentally friendly manufacturing practices across various industries. The implications of this project extend far beyond the walls of the Cognac plant, highlighting the potential for significant global impact in the fight against climate change.

Source:Verallia with additional information added by GlassBalkan