THERMOSEAL DOUBLES CAPACITY TO MEET GROWING DEMAND FOR HIGH-PERFORMANCE SPACER BARS

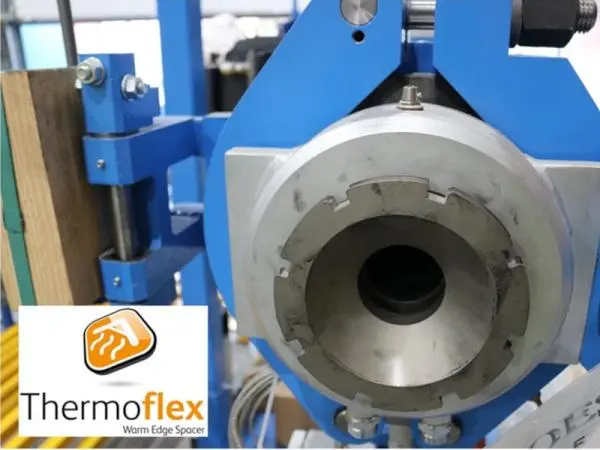

Thermoseal, the UK’s market leader in spacer bars, has recently invested in a new twin-strand extruder to double its capacity and to meet the demand for high-performance flexible warm edge spacer bars. The extruder will sit alongside the two existing models and can produce all thicknesses of Thermoflex, including 4.8mm, 6.3mm, and 7.3mm, and air spaces up to 28mm, in twin strands. The new equipment is quicker than the company’s existing machines, allowing the production of more than double the quantity of product per shift on certain product types.

According to Mark Hickox, Thermoseal Group’s Sales Director, their success in the market comes from their ability to control the whole process from compounding the rubber to delivering it to the customer. This control ensures that all products pass rigorous testing, and the quality is guaranteed when delivered.

The investment in the new extruder not only increases the capacity of the standard 20mm Thermoflex but also prepares the company for increased demand in other sizes. The upcoming Future Homes Standard in 2025, which requires windows with lower U-values, will demand more units with different thicknesses of glass and spacer bars. Companies that prepare for these changes now will be the ones ready to take on extra work when the new legislation comes into force.

The new extruder will also support Thermoseal Group’s growing export market, which is expected to grow significantly as more countries adopt stricter standards for energy-efficient building materials. The company plans to continually develop higher performing products, reduce their cost and energy consumption, and help people invest in energy-saving products for their homes.

Contact Thermoseal Group to learn more about their range of products and services, including equipment, production methods, and automated or manual production options. Call 0121 331 3955 or visit www.thermosealgroup.com.

Source: Thermoseal Group with additional information added by GlassBalkan