A Clear Defense Against Modern Threats: Eastman Saflex™ PVB Interlayers Provide Building Security

As glass architecture becomes increasingly popular in building design, concerns about building security have risen. Eastman Saflex™ PVB interlayers provide a solution for architects to protect people and property from modern threats such as active shooters, burglary, and other intentional attacks.

Saflex interlayers have a long history in safety applications for accidental and natural causes. In the event of broken glass, interlayer glazing causes the glass to adhere to the interlayer, preventing shards from falling or flying and causing injury. However, architects must now consider intentional attacks on or threats to glass architecture.

Saflex PVB interlayers in laminated glass provide a critical line of defense, tested according to industry standards for building safety and security. The interlayers can deter or delay attackers from gaining entry to buildings, reducing or preventing human injury and property damage.

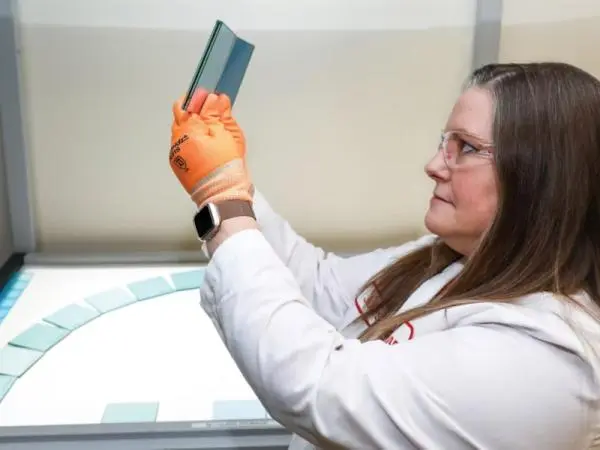

Recent glass testing for ASTM International’s newest standard, F3561, proves Saflex interlayers’ effectiveness against forced entry in a simulated active shooter attack. The interlayers provide defense against single and repetitive forced-entry strikes to glass and can meet all levels of protection, from one to eight.

Saflex Clear, Secure, and Storm PVB interlayers can meet different levels of protection, while composite interlayers like Saflex Storm reach higher performance levels in security testing while maintaining thinner laminated glass constructions.

Saflex interlayers are ideal for use in educational, industrial, and commercial buildings, which face an increasing number of manufactured attacks and threats.

For architects looking to enhance building security, Saflex interlayers provide a proven security solution they can be confident in. Learn more about Saflex security applications and data at saflex.com/saflex-guide/basics/security.

Please note that these products have been evaluated for interlayer capability and should be used as a guide. In cases where certification is necessary, glass fabricators must complete the testing as they are producing the laminated glass specimens used in the project.

Source: www.saflex.com with additional information added by GlassBalkan