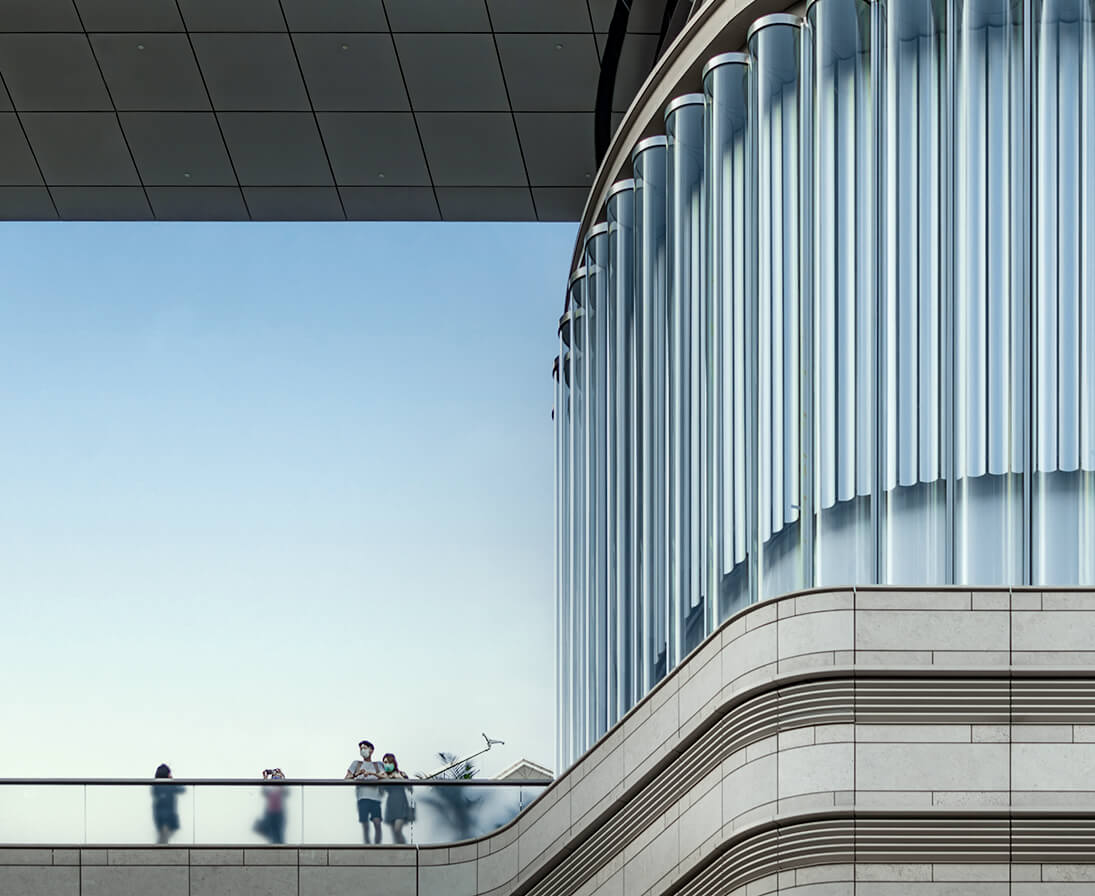

Walking past K11 MUSEA in Victoria Dockside, the building immediately draws the eye. Its exterior is composed of 475 massive glass tubes, each nine meters tall, one meter in diameter, and weighing approximately two tonnes. From a distance, they appear almost weightless, but up close, the craftsmanship is astonishing. Every curve, reflection, and polished edge contributes to an optical illusion that makes the facade seem alive.

The tubes were realized by Cricursa, the Barcelona-based glass manufacturer, years before the building’s 2019 inauguration. The architects at SO-IL envisioned a facade that changes subtly with light and movement, blending solidity with transparency, a challenge that demanded technical precision at an unprecedented scale.

Cricursa began with flat Low-Iron annealed glass panels, 10 mm and 12 mm thick. These panels were then bent into perfect cylinders using CNC-controlled hot bending, with a strict 450 mm radius for uniform curvature. Each half-tube was laminated with SentryGlas® interlayers in an autoclave to ensure structural strength and durability, while edges were polished on all four sides to preserve the clarity and continuity of the glass lines.

To achieve the final facade, 372 custom units were produced and arranged to create the visual effect of 475 individual tubes, covering over 3,900 square meters. The lamination process, combined with precise bending, allowed the tubes to withstand structural loads while maintaining optical clarity. The result is a surface where reflections layer, light shifts with movement, and subtle distortions enhance the sense of depth.

The K11 MUSEA facade demonstrates how engineering meets artistry: through careful selection of glass type, thickness, lamination, and bending methods, Cricursa transformed a daring architectural idea into a tangible reality. Each tube is not just a component, it’s a testament to the technical skill and precision required to make glass appear effortless.

Source: seele.com with additional information added by Glass Balkan