Trade fabricator Modplan Ltd has made another major step in expanding its production capacity with the installation of a Supercut 6 Machining Centre, supplied by Avantek Machinery. The new system is now fully operational at Modplan’s uPVC fabrication facility in Newport, Gwent, further strengthening the company’s manufacturing efficiency and technical capability.

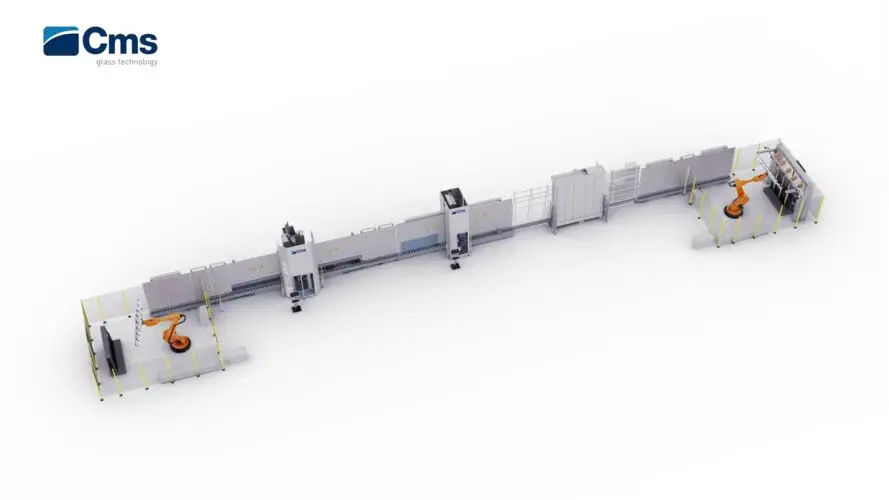

The Supercut 6 is a next-generation, fully automated cutting and machining centre developed for the high-speed fabrication of uPVC and aluminium window and door profiles. It integrates six controlled axes, intelligent software, and multi-tool machining heads, allowing it to perform precise cutting, routing, drilling, and marking in a single, continuous process. The system’s automatic profile recognition and quick-change tooling deliver faster cycle times and eliminate manual intervention, ensuring accuracy and repeatability in large-scale production.

Heidi Sachs, Managing Director at Modplan, said: “The addition of the Supercut 6 represents a significant investment in our long-term manufacturing strategy. It allows us to handle increasing order volumes while maintaining the precision, speed, and quality our customers expect.”

This installation marks another milestone in Modplan’s ongoing investment programme, which has recently included upgrades to extrusion lines, welding stations, and quality control systems. With over five decades of industry expertise, Modplan continues to combine advanced automation with strong customer partnerships to deliver premium-quality window, door, and conservatory solutions to the UK trade market.

Source: Modplan Ltd with additional information added by Glass Balkan