Glass has always been recyclable, but the industry is now entering a new era of sustainability thanks to advanced recycling technologies and low-emission production methods. Instead of just melting old bottles, manufacturers are rethinking the entire lifecycle of glass, using smarter machines, better material separation, and cleaner melting technologies.

High-Tech Recycling Systems

Leading companies like Binder+Co and TRENNSO‑TECHNIK® are equipping recycling plants with automated screening, colour sorting, and contaminant removal systems. These machines can deliver cullet (recycled glass) at 99.9% purity, making it ready for immediate reuse in furnaces without additional processing. Zippe GmbH goes even further, designing smart conveyor systems that continuously return broken glass directly into production, cutting waste in real time.

Green Melting Technologies

Beyond recycling, the melting process is going electric. French company Fives Group developed the Prium E-Melt, an all-electric furnace producing container glass with 60% lower CO₂ emissions. Hybrid models like Prium Eco-Flex combine gas and electricity, offering flexibility while reducing environmental impact.

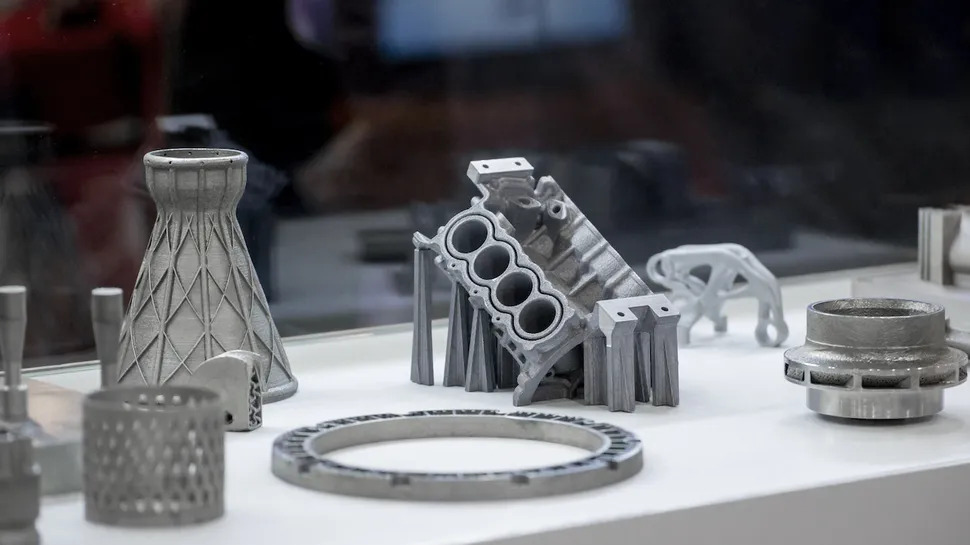

Innovative Materials from Waste

Eco-friendly glass is evolving too. Researchers have created oxyfluoride glasses using recycled photovoltaic (PV) panels. These glasses melt at lower temperatures and retain excellent clarity, showing promise for both construction and tech applications.

Decentralized Recycling for Real Impact

To make recycling more accessible, O-I Glass launched MOGRA, a mobile glass recycling unit that can be deployed in remote areas. This truck-mounted system allows local glass collection and processing, helping communities close the recycling loop without major infrastructure.

Glass is no longer just recyclable, it’s becoming smarter, cleaner, and more circular. As new technologies gain ground, the glass industry is proving it can lead the way toward a truly sustainable materials economy.

Source: Glass Balkan