Glass is one of the world’s most versatile materials, yet its natural fragility often limits its use. Chemical tempering has transformed this reality, providing unmatched strength without compromising clarity. Leading this innovation is TK S.r.l., an Italian manufacturer renowned for precision engineering in glass processing. The company has now released a new 3D video offering a detailed look inside its TK Chemical Temper ovens, revealing how this advanced technology works.

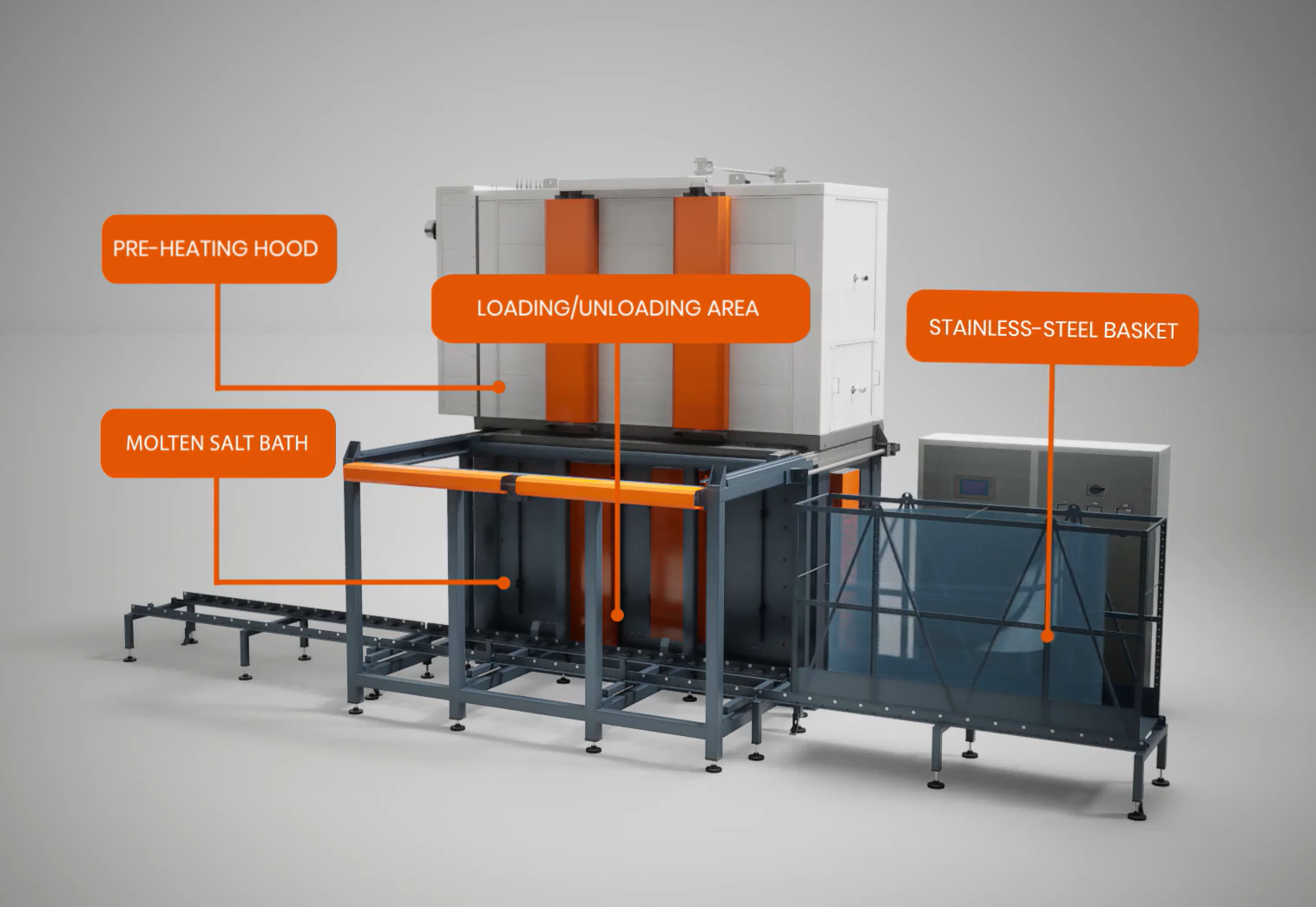

Unlike traditional thermal tempering, chemical strengthening relies on ion exchange at the glass surface. The process immerses the glass in a molten potassium salt bath at around 450°C, where smaller sodium ions are replaced by larger potassium ions, creating a powerful compressive layer. TK sources its potassium salts with over 99% purity, ensuring consistent performance and exceptional quality.

Advantages Beyond Comparison

Chemical tempering provides unique benefits that make it indispensable in specialized industries: it can strengthen ultra-thin glass (down to 0.5 mm), process complex or curved shapes without distortion, and maintain perfect optical clarity. The result is glass with superior strength and durability, ideal for architectural, automotive, optical, military, and electronic applications.

Transparency Through Technology

The new 3D video offers an “inside-the-machine” perspective of the entire tempering cycle, transforming a complex industrial process into an accessible, visual experience. It serves as both a training and communication tool, enhancing technical understanding worldwide.

Fully designed and produced in Italy, TK’s ovens embody Made in Italy engineering excellence. Together with TKonnect 4.0, the company’s advanced remote support system, TK continues to lead in transparency, innovation, and service, with equipment installed in over 70 countries worldwide.

Source: tkitaly.com with additional information added by Glass Balkan