Every insulated glass unit (IGU) has a story, and one of its quietest but most important characters is the desiccant. Hidden deep inside the spacer bar, this tiny, unseen material works tirelessly to keep windows clear and free from condensation through cold winters and humid nights.

Desiccant first appeared in double glazing during the 1950s, when condensation was one of the biggest challenges in the industry. Even when seals were perfect, moisture trapped between the panes would fog the glass as temperatures dropped. The solution came from the packaging world, where desiccants were already being used to protect goods from humidity during transport. The idea quickly transformed the performance of insulated glass.

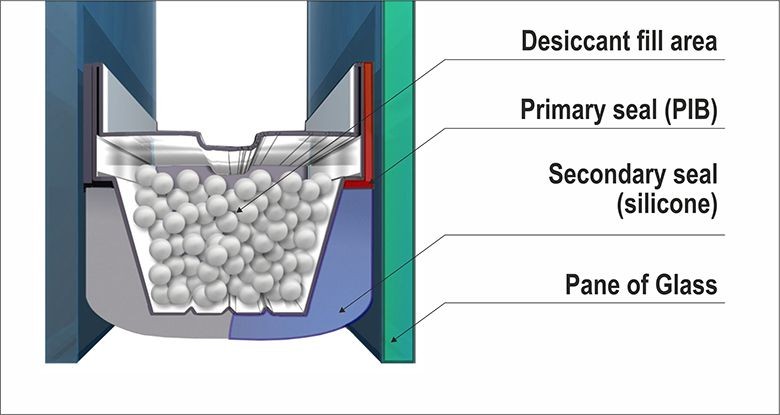

The image above shows where the desiccant sits inside an insulated glass unit, contained within the spacer bar to keep the cavity dry and condensation-free

Today’s desiccants are far more advanced. Made from molecular sieve beads, each granule contains thousands of microscopic pores that absorb and permanently lock away moisture. Without them, glass units would mist, coatings would corrode, and their lifespan would be drastically shortened.

At Euroview Architectural Glass, desiccant management is a precise, controlled process. Storage conditions are checked daily, fill systems are calibrated to the gram, and every finished unit undergoes dew point testing to ensure long-term clarity and performance. Though invisible, this small material plays a mighty role, proving that sometimes, the smallest details make the biggest difference.

Source: www.euroview.glass with additional information added by Glass Balkan