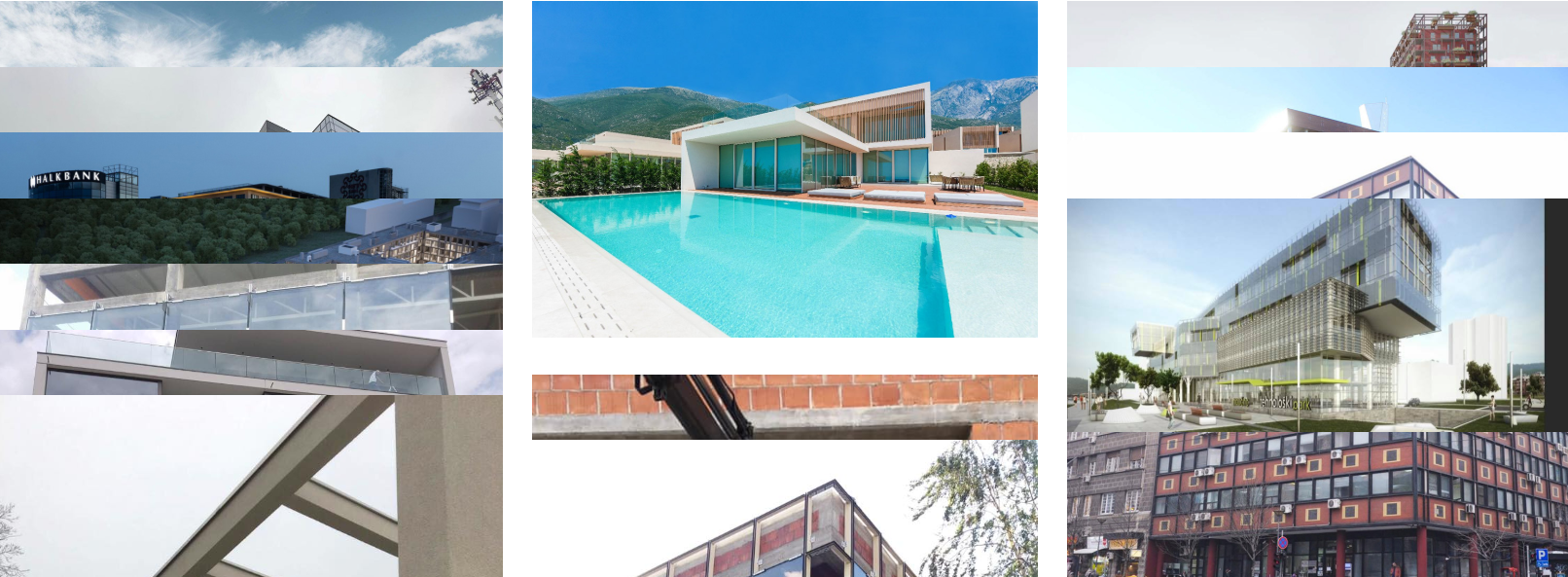

Founded in 1995, Termopan Glass has established itself as a reliable provider of flat-glass solutions across residential, commercial, and architectural projects. Based in Bujanovac, Serbia, the company combines decades of experience with technical expertise in glass processing, tempering, and installation. This enables Termopan Glass to deliver a comprehensive, turnkey service to clients seeking both high-quality materials and professional glazing solutions.

Termopan Glass sources its raw glass exclusively from leading European manufacturers such as Guardian Glass and AGC. These suppliers are renowned for producing high-performance float glass with superior durability, clarity, and thermal efficiency, essential qualities in modern architecture. By integrating these premium materials into its workflow, the company ensures that each project meets stringent quality and safety standards.

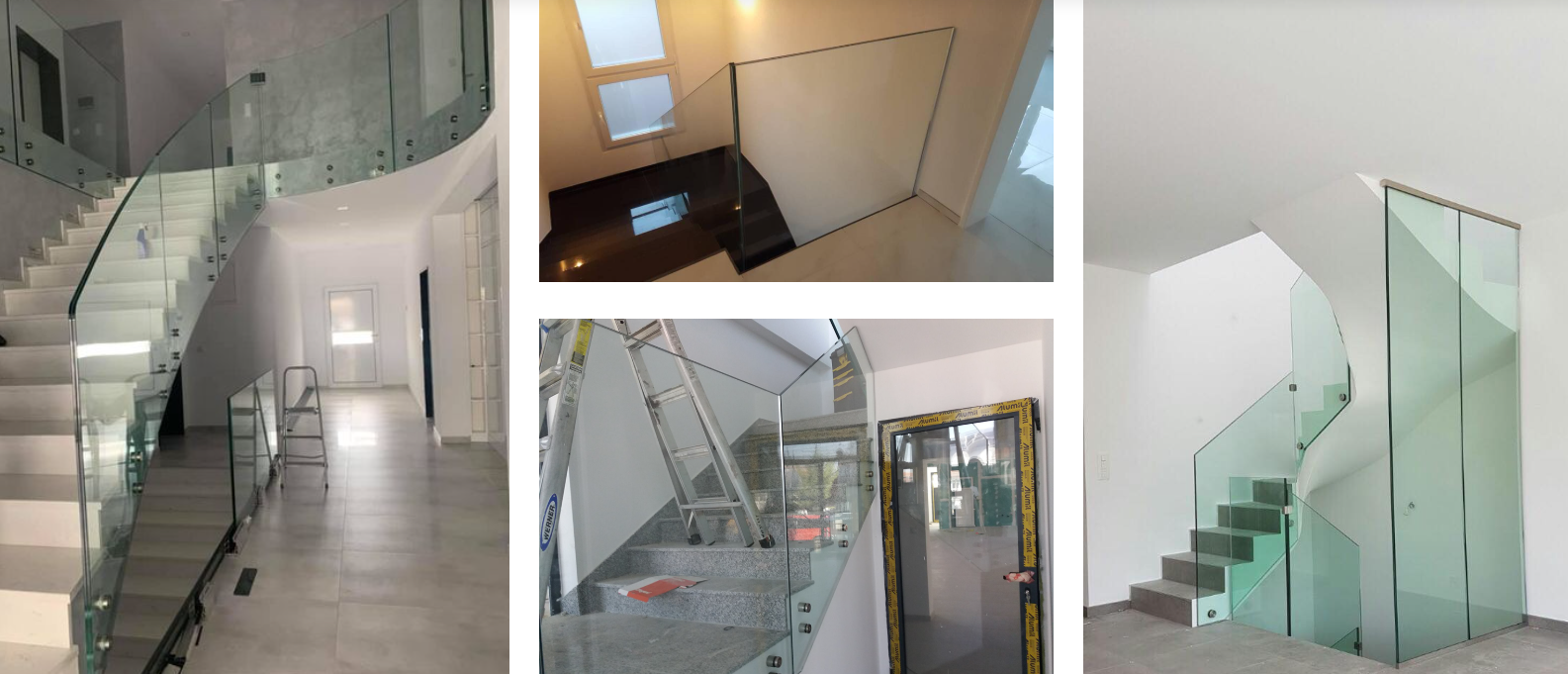

The company offers a wide range of glass applications, including office partitions, glass walls, stair railings with tempered curved glass, balcony glazing, and bathroom partitions. Unlike firms that solely distribute raw glass, Termopan Glass provides end-to-end services: project design, technical consultation, precise processing, installation, and finishing. This approach aligns with contemporary industry practices, where mid-sized regional processors bridge the gap between large-scale glass manufacturers and local construction projects.

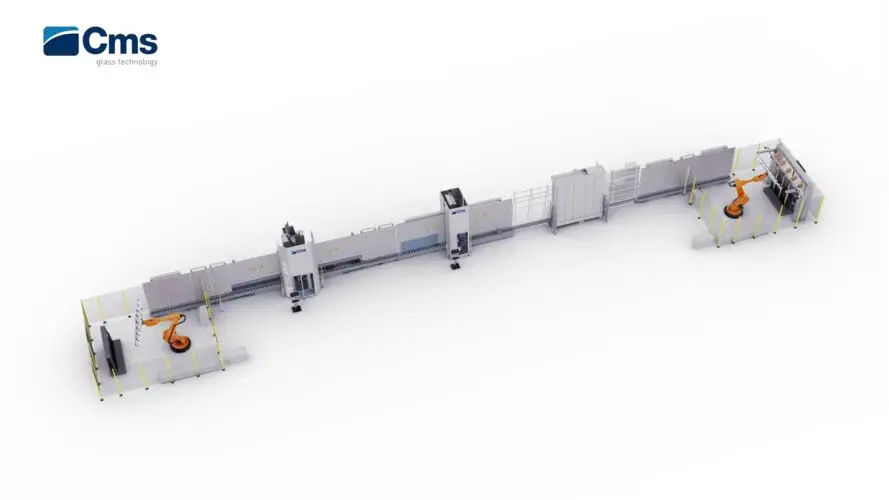

Technical precision is central to the company’s operations. In the architectural glazing industry, tempered glass is a key safety standard. The tempering process involves heating glass to approximately 650–700°C and rapidly cooling it to induce internal stresses, increasing strength up to five times compared to standard annealed glass. Tempered glass also shatters into small, less dangerous fragments if broken, making it suitable for balconies, railings, shower cabins, and high-traffic partitions. Termopan Glass ensures that all cutting, drilling, and edge-finishing occur prior to tempering, a critical requirement in the sector. For projects requiring additional safety or acoustic insulation, laminated glass and insulated glazing units (IGUs) are also incorporated.

Compliance with European and local building standards is essential. EN 12150 certification governs thermally tempered glass, while proper installation ensures structural integrity and safety. Termopan Glass’s technical expertise extends to precise measurement, edge finishing, and installation techniques that prevent stress fractures, maintain structural stability, and ensure longevity. Environmental responsibility is also an industry consideration: recycling and proper handling of end-of-life glass (cullet) are increasingly important to reduce energy consumption and support sustainability initiatives.

Operating as TERMOPAN-GLASS DOO BUJANOVAC, the company employs approximately 30–35 staff members and has achieved consistent regional growth. Its dual focus on processing and glazing positions it as a vital link in the European flat-glass value chain, transforming raw glass into finished, ready-to-install architectural products.

In conclusion, Termopan Glass exemplifies the standards, precision, and technical knowledge required in the modern glazing industry. By combining premium materials, advanced processing, and expert installation, the company provides durable, safe, and aesthetically refined solutions, making it a trusted partner for complex architectural glass projects.

Source: Glass Balkan