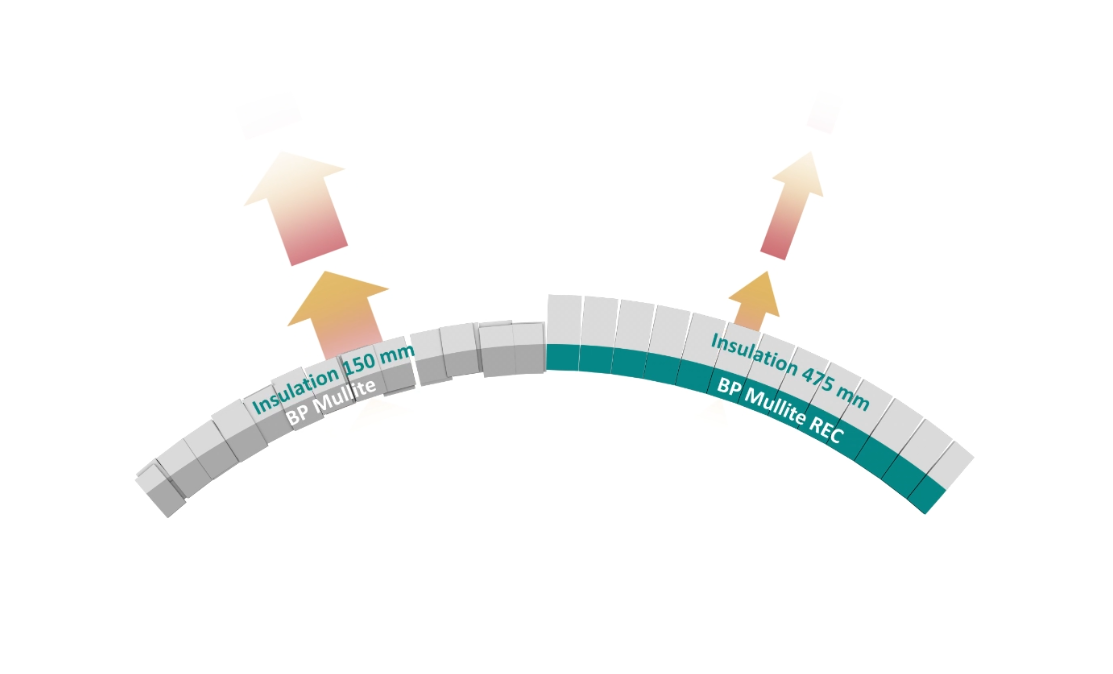

Reducing energy consumption and CO2 emissions in glass melting furnaces is a major focus for the glass industry, especially for reinforcement glass fibre production. One effective method to achieve this is by increasing the insulation thickness of furnace superstructures, which minimizes heat loss. However, this approach presents technical challenges. Thicker insulation increases the weight on the furnace crown blocks, and as operating temperatures rise, the risk of creep, slow deformation under sustained high temperature and stress, also increases. This can cause the crown to sag or fail if the material’s mechanical limits are surpassed.

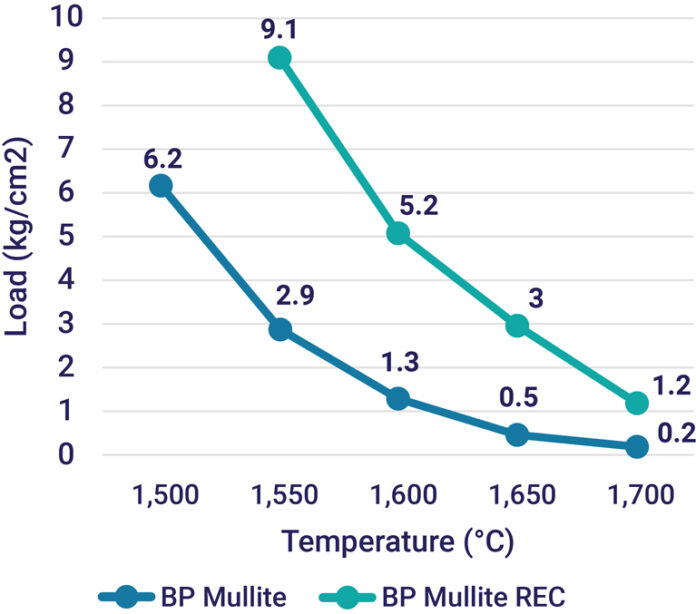

To address these issues, SEFPRO developed the BP Mullite REC superstructure material, offering superior creep resistance, up to six times greater at 1,700°C compared to standard materials. This allows furnace crowns to carry heavier insulation loads at elevated temperatures, enabling operation at crown temperatures more than 100°C higher than before. Higher crown temperatures contribute to improved glass melting efficiency and production performance.

BP Mullite REC is particularly adapted to oxy-fuel combustion furnaces, which operate with higher flame temperatures. The material ensures the integrity and stability of the refractory crown throughout the furnace’s campaign life, which is critical for consistent high performance.

By using BP Mullite REC, reinforcement glass fibre furnaces can reduce thermal heat losses by around 60%, significantly cutting energy consumption and lowering CO2 emissions. SEFPRO also offers numerical simulation services to assess furnace crown stresses and optimize insulation designs, helping manufacturers determine when BP Mullite REC is beneficial. This innovation represents a meaningful step toward more sustainable glass production processes.

Source: SEFPRO with additional information added by Glass Balkan