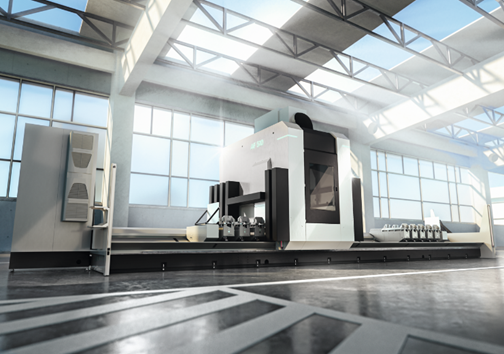

Schüco, one of Europe’s leading manufacturers of window, door, and façade systems, has introduced a new generation of CNC technology – the Schüco AF 510, a high-performance 5-axis CNC machine that delivers superior precision, energy efficiency, and advanced production process. This advanced technology is now available on the Albanian and Kosovo market through ALUKOENIGSTAHL d.o.o., the exclusive representative of the Schüco.

Schüco AF 510 represents a comprehensive solution for almost all processing tasks in the field of metal construction. The machine enables simultaneous processing of larger cross-sections with precise cutting, thanks to powerful motor technology, a new control concept, and automated six-sided profile processing. The new model succeeds the previous version, AF 500, and brings additional functionalities for greater productivity and a reduced carbon footprint (CO₂).

Thanks to absolute position measurement systems, axis referencing is no longer required, and independent control of clamping systems allows simultaneous group operation, significantly reducing setup time and processing cycle duration.

Efficient fabrication

The Schüco AF 510 CNC machine impresses with a high-performance spindle, meaning it also delivers optimal performance in the V8 range. At the same time, the design and the control unit have also been modernised. This is because the previous operating concept has been completely optimised as well as simplified. New, high-quality and more age-resistant bumpers mean photoelectric barriers and safety saws are no longer needed.

The new swarf extractor also simplifies the reliable cleaning of the system during operation and at the end of the shift. An extraction unit can also be installed. Tight inner side corners and service hatches with quick-release locks and adjustable hinges ensure that the machine remains clean and can be serviced, even in areas that are difficult to reach. A sensor-controlled pressure monitor indicates whether a profile is tensioned or not. The broken tool check can therefore be conducted quickly and easily.

With a function for monitoring vibration, a high-performance 22 kW spindle and new spindle cooling system, the Schüco AF 510 machine is also ideal for Industry 4.0. Thanks to the new adjustable feet with fine-pitch thread, the machine can now also be set up even faster and with more precision.

Long-term benefits

The Schüco AF 510 CNC machine impresses with its intelligent energy recovery. When using the brakes for the CNC axes, the kinetic energy of the axes is converted into electrical energy, which prevents it from escaping as heat. In doing so, the drive motors function as generators for the conversion to electrical energy. The frequency converter regulates the recovery of this energy, meaning that any unused power can be utilised elsewhere or can be fed back into the network. In addition, liquid cooling is used, which consumes less power compared to machines with conventional air cooling.

Integration and local support

Thanks to an exclusive partnership with AluKönigStahl, metal producers in Albania and Kosovo have access to the latest Schüco solutions, expert technical support, education, and service offerings. AluKönigStahl ensures seamless integration of Schüco technology into existing production processes, providing full logistical and technical support. Schüco AF 510 is not just an advanced CNC machine. It is an investment in more efficient, safer, and sustainable production.

More information is available on the website https://aks-fabrication.com/al/ or directly via email at the address [email protected]

Take advantage of special discounts!Until the end of 2025, AluKönigStahl is offering special discounts on selected Schüco machines. This is a perfect opportunity to upgrade your production with cutting-edge technology. Don’t miss this unique chance!

More information about promotional packages can be found on the website

aks-fabrication.com

Source: ALUKOENIGSTAHL d.o.o with additional information added by GlassBalkan

![Glassbel and HEGLA at the new Laserbird installation in Klaipėda. [Photo by HEGLA boraident]](https://glassbalkan.com/wp-content/uploads/2025/06/download.jfif-4-1-Edited.jpg)