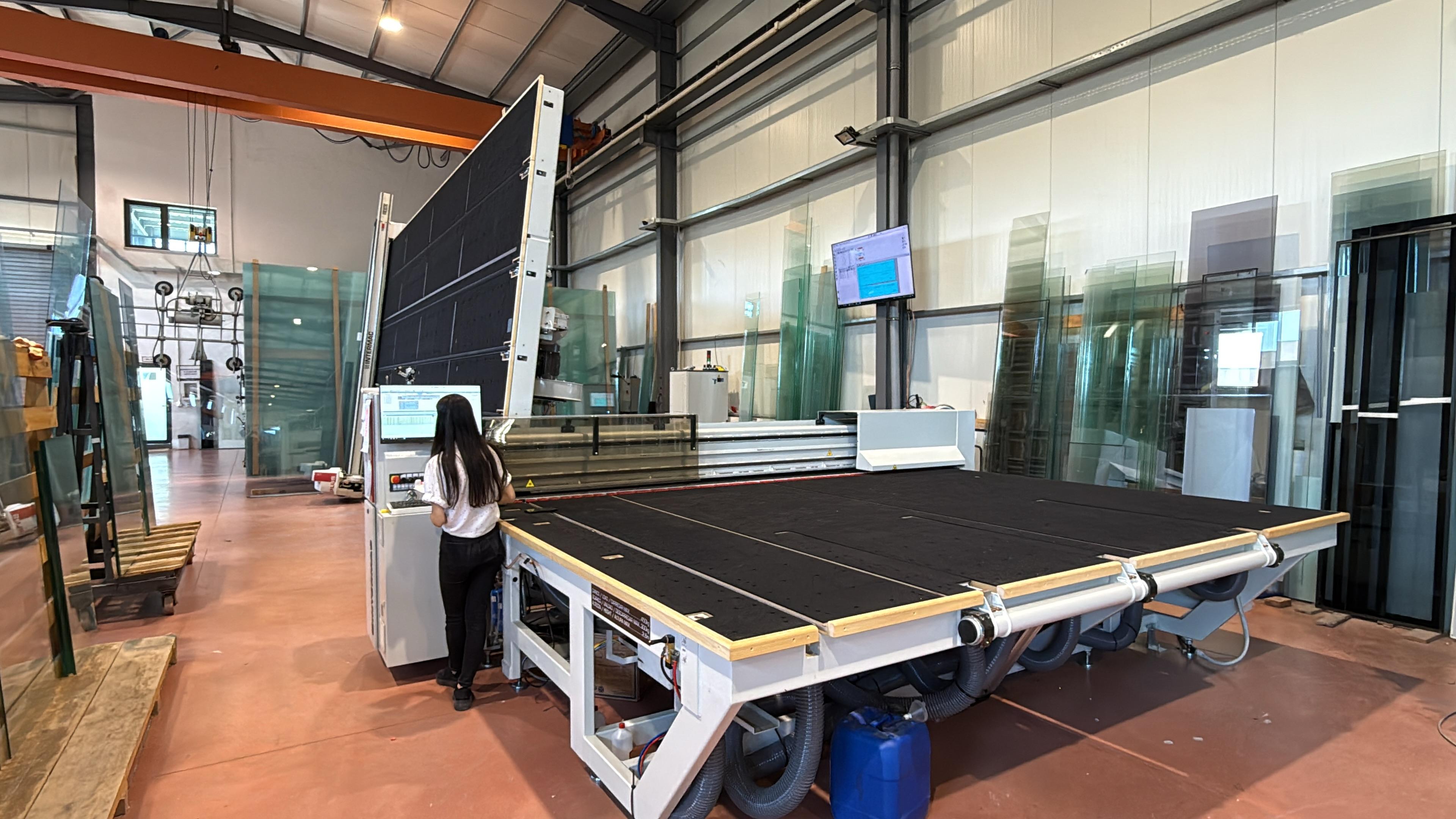

Tirana, Albania – Roland Glass Company, a leader in the Albanian glass industry, is proud to announce its continued investment in state-of-the-art technology with the acquisition of two new machines from Biesse Group: the Intermac Genius 61 CT Plus and the Genius 37 LM. These strategic investments underscore Roland Glass Company’s commitment to meeting evolving market demands and further solidifying its position as an innovator in the region.

Responding to Market Demands with Cutting-Edge Solutions

Today’s market demands a significant shift in manufacturing processes. Companies must be equipped to handle a high volume of orders while simultaneously upholding the highest quality standards. This is coupled with the critical need for product customization, swift and predictable delivery times, and the ability to satisfy the stringent requirements of even the most highly automated industries.

Roland Glass Company is proactively responding to these challenges with technological solutions that guarantee superior quality and reliable performance over the long term. The new Intermac Genius CT-A series, specifically designed for float glass cutting, is ideal for businesses of all sizes. These cutting tables optimize material usage for both regular and jumbo-sized sheets, maintaining exceptional cutting precision over time and ensuring an excellent return on investment.

Unlocking New Possibilities with Intermac Technology

The Intermac Genius 61 CT Plus and Genius 37 LM bring a host of benefits that will directly translate into enhanced capabilities for Roland Glass Company and its clients:

- Customizable Solutions For Every Requirement: Offering unparalleled flexibility to meet diverse project needs.

- Guaranteed Reliability Over Time: Ensuring consistent, high-quality output for every order.

- Maximum Machining Flexibility: Adapting to a wide range of glass processing demands.

- Cutting-Edge Technology: Leveraging the latest advancements in glass cutting.

- Cutting Precision With Simple And Intuitive Technology: Delivering accuracy with user-friendly operation.

These machines will lead to reduced cycle times and increased productivity. The advanced management of axle speed via PC, combined with the high quality of all electronic and mechanical components, optimizes machining times, guaranteeing both flexibility and dynamism in production.

Intelligent Integration: The Power of Comby Lines

The new Intermac machines are integral to the concept of Comby lines, which can be integrated into even smaller spaces for cutting both float and laminated glass, significantly boosting productivity. These lines are the result of a clever combination between the Genius CT-A cutting tables (for float glass cutting) and the Genius LM tables (for laminated glass cutting).

Comby Lines represent a perfect synergy of these two glass-cutting technologies, ensuring high productivity through key features such as:

- Belts on the float table

- Suction cups on the float cutting bridge

- Intermac-patented vertical buffer on the float table

- Large belts on the laminate cutting module

- Break-out bar on the laminate table

Partner with Roland Glass Company

“We invite our valued clients and prospective partners to visit our factory in Tirana to see these cutting-edge machines in action and discuss in detail how Roland Glass Company can collaborate with you to achieve your project goals. Experience firsthand our commitment to innovation, quality, and customer satisfaction” – Roland FETO, CEO of Roland Glass.

- Contact us today to schedule your visit and explore the future of glass manufacturing with Roland Glass Company.

Source: GlassBalkan