The insulated glazing unit (IGU) manufacturing process demands precision and efficiency at every stage.

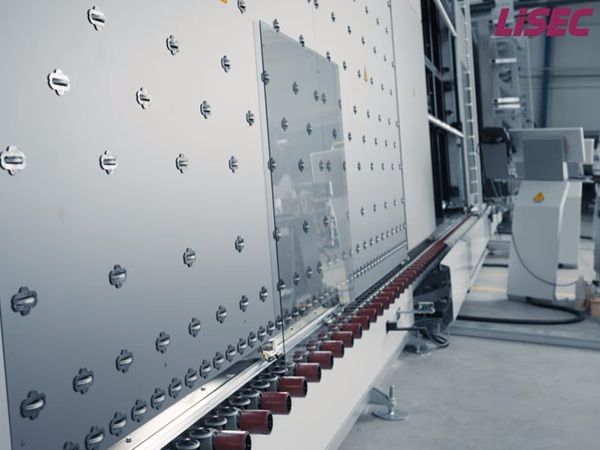

One critical element often overlooked is the handling and processing of rigid spacers. Inefficient spacer integration can bottleneck production, impacting overall output and potentially compromising the quality of the finished product. LiSEC’s revolutionary RHF line addresses these challenges directly, offering unparalleled performance and flexibility in rigid spacer processing.

The LiSEC RHF line represents a significant advancement in IGU manufacturing technology. Its innovative design focuses on optimizing every aspect of rigid spacer handling, from initial alignment to final placement. This results in a streamlined process that maximizes efficiency and minimizes the risk of errors.

Key highlights of the RHF line include:

- Alignment and Handling: fixed and dynamically moveable grippers for perfect frame positioning.

- Integration: automatic frame pickup and placement by a six-axis articulated-arm robot.

- Flexibility: suitable for all common rigid spacer types and Georgian bars.

- Process Stability: continuous operation for increased production output.

- Versatility: extended spatial possibilities thanks to the robot’s large range of motion.

LiSEC RHF line isn’t just an upgrade; it’s a transformation in rigid spacer processing. By combining precision automation, flexibility, and continuous operation, the RHF line empowers IGU manufacturers to achieve new levels of efficiency, precision, and profitability. If you’re looking to optimize your production process and stay ahead of the curve, the LiSEC RHF line is a solution worth exploring.

Source:LiSEC with additional information added by GlassBalkan