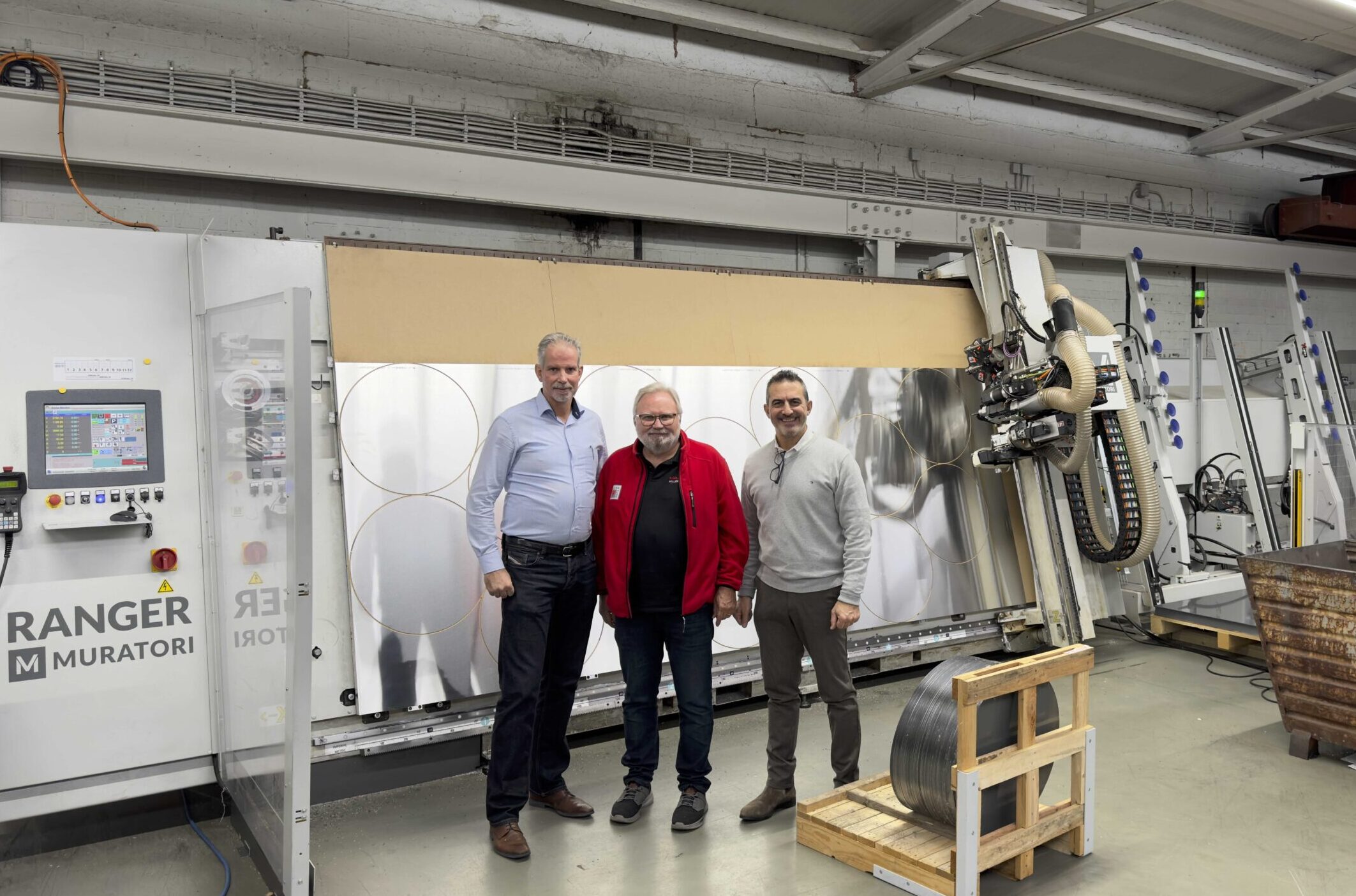

RCN Solutions, a prominent name in safety glass technology, is reaffirming its commitment to chemical tempering as a key process in the evolution of glass manufacturing. Since 2017, the company has promoted this method for its superior breakage and impact resistance, especially compared to traditional thermal tempering.

A Solution for Lightweight, High-Performance Installations

Today’s architectural and industrial glass trends are moving toward lighter, thinner, and stronger solutions. Chemical tempering is increasingly valued for enabling such designs, particularly with ultra-thin glass from 0.5 to 0.7 millimetres. When laminated between other sheets, chemically tempered glass enhances both strength and compliance with international safety standards, making it ideal for façades, interior partitions, and mobile devices.

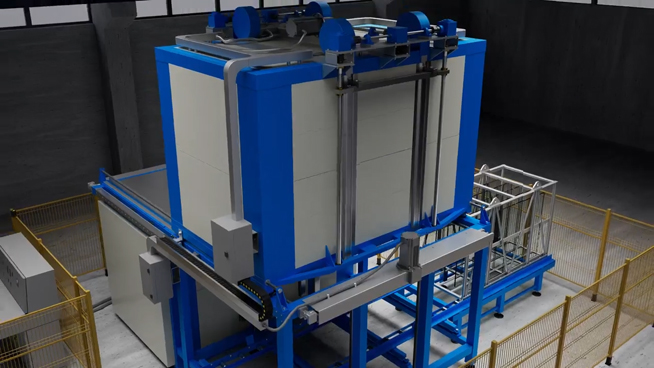

Easy Process, High Efficiency

RCN’s chemical tempering system is designed for ease of use. Unlike thermal tempering, it does not require highly specialized personnel, nor does it need frequent changes of potassium salts, just periodic replenishment. Moreover, the energy consumption is optimized: pre-heating at 300°C, followed by a 450°C chemical bath, allows the system to run on only 15% of total installed power after reaching target temperature.

Purity Matters: 99% Certified Potassium Salts

RCN also emphasizes the importance of material purity. Their potassium salts boast 99% purity, a crucial factor in achieving consistent tempering quality. Certified analysis backs this standard, reflecting the company’s rigorous attention to detail.

Source: RCN with additional information added by Glass Balkan