As demand for high-performance laminated glass continues to rise, LiSEC is setting new industry standards with cutting-edge retrofits that transform existing systems into future-ready powerhouses. These upgrades not only enhance the precision and speed of laminated glass cutting but also extend the life and efficiency of LiSEC machines already in operation.

Precision Cutting with Upgraded Heads

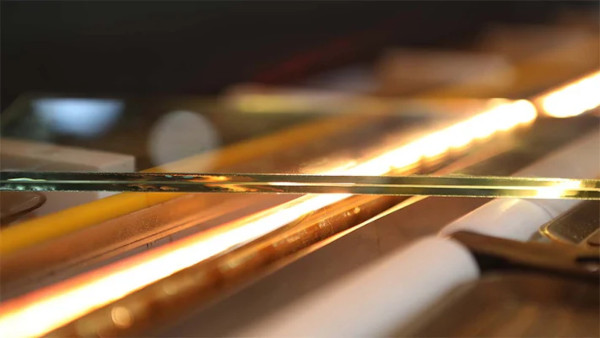

LiSEC’s retrofittable cutting head, originally developed for its latest VSL-A models, is now available for VB series machines (VB-33, VB-45, VB-60). This upgrade significantly enhances edge quality and strength. The design prevents fluid ingress and reduces friction, maintaining consistent cutting pressure and preventing glass splinters, which is crucial for both safety and product quality.

Minimized Stress and Higher Break Quality

The integration of an “anti-stress” suction bar in the cutting process helps reduce internal stresses on the laminated glass, particularly important when dealing with inconsistent material quality. This ensures cleaner breaks and reduces waste, increasing production reliability.

Shorter Heating Times for Faster Output

Efficiency takes a leap forward with the SIR heating retrofit kit. Using segmented infrared technology, it cuts foil heating time from 25 seconds to under 10 for 44.2 laminated glass. This significantly boosts throughput while reducing energy consumption, two essential goals for competitive glass manufacturers.

Uninterrupted Production and Smarter Cutting

The “Cut remnant plate first” software upgrade allows remnant plates to be removed without halting production. Additionally, a new Z-cut optimization software enables overlapping cutting processes, minimizing idle time between manual and automated steps.

A Future-Proof Investment

With these retrofits, LiSEC empowers glass manufacturers to get more out of their existing equipment. Enhanced precision, faster cycle times, and streamlined workflows make these upgrades a smart investment for any company striving for operational excellence in laminated glass cutting.

Source: LiSEC with additional information added by Glass Balkan