At Vitrum in Milan, HEGLA Group showcased groundbreaking advancements in glass processing technology, focusing on thin glass, laminated safety glass (LSG) cutting, laser applications, and an industry-specific ERP system.

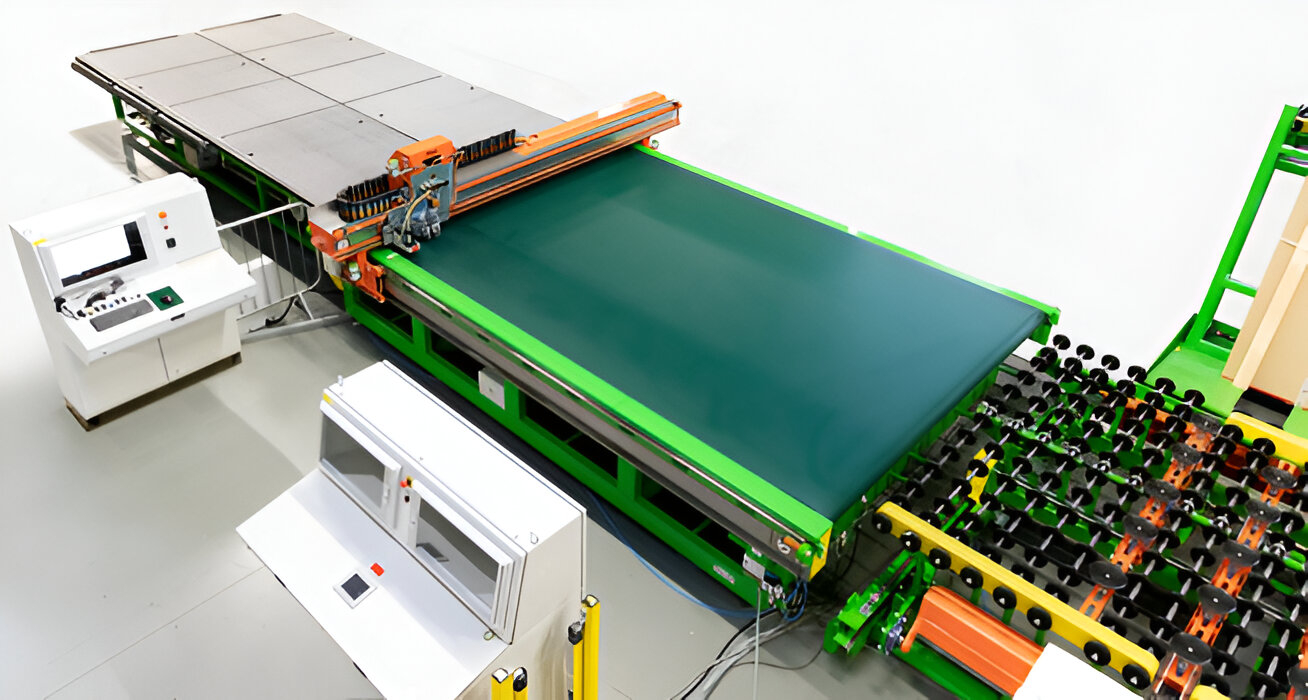

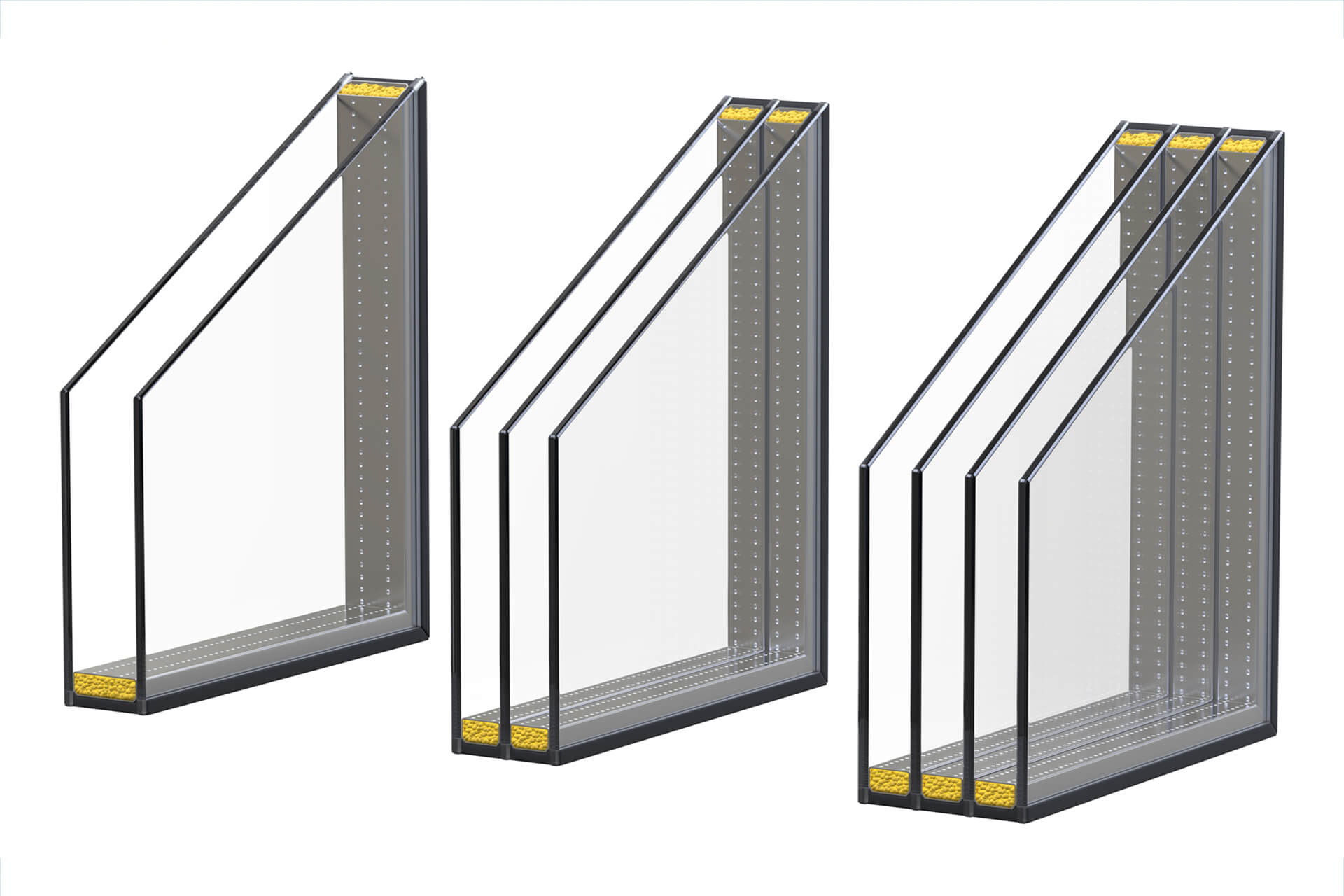

A key highlight was the use of ultra-thin glass, as thin as 0.5 mm, in triple glazing. This innovation allows for lighter, slimmer window units while maintaining excellent thermal insulation. Thin borosilicate glass, known for heat and break resistance, demands precise handling. HEGLA’s automated cutting technology with a specialized cutting head ensures strong, uniform edges suitable for insulating glass units combined with advanced spacers like TPS.

HEGLA also introduced a new fully automated LSG cutting table that combines features from its AdvaLam and ProLam systems. Enhanced with a laser diode heater, it increases productivity by 20% while reducing cycle times, shifting control from operator to machine for improved efficiency.

Laser technology adds functional value, enabling bird protection patterns, RF transparency, and heat able glass. HEGLA’s laser markings are durable and colour-fast for over 20 years. New processes include a high-quality laser edge coating and the compact UC-Stamp marking system for precise identification.

The glass365 ERP platform, based on Microsoft Dynamics 365, offers mobile access, AI-driven order processing, and Office 365 integration. It automates email order reading and simplifies production scheduling, with a new MES/PPS solution in development.

HEGLA’s innovations empower the glass industry with smarter, faster, and higher-quality manufacturing solutions.

Source: HEGLA Group with additional information added by Glass Balkan