In the demanding landscape of glass manufacturing, HEGLA has introduced a revolutionary solution tailored for one of the most sensitive materials in the industry, thin float glass. The Galactic float glass cutting system is purpose-built to meet the highest standards of accuracy, care, and throughput for glass sheets that are increasingly used in architectural, automotive, and high-tech applications.

Belt-Driven Brilliance

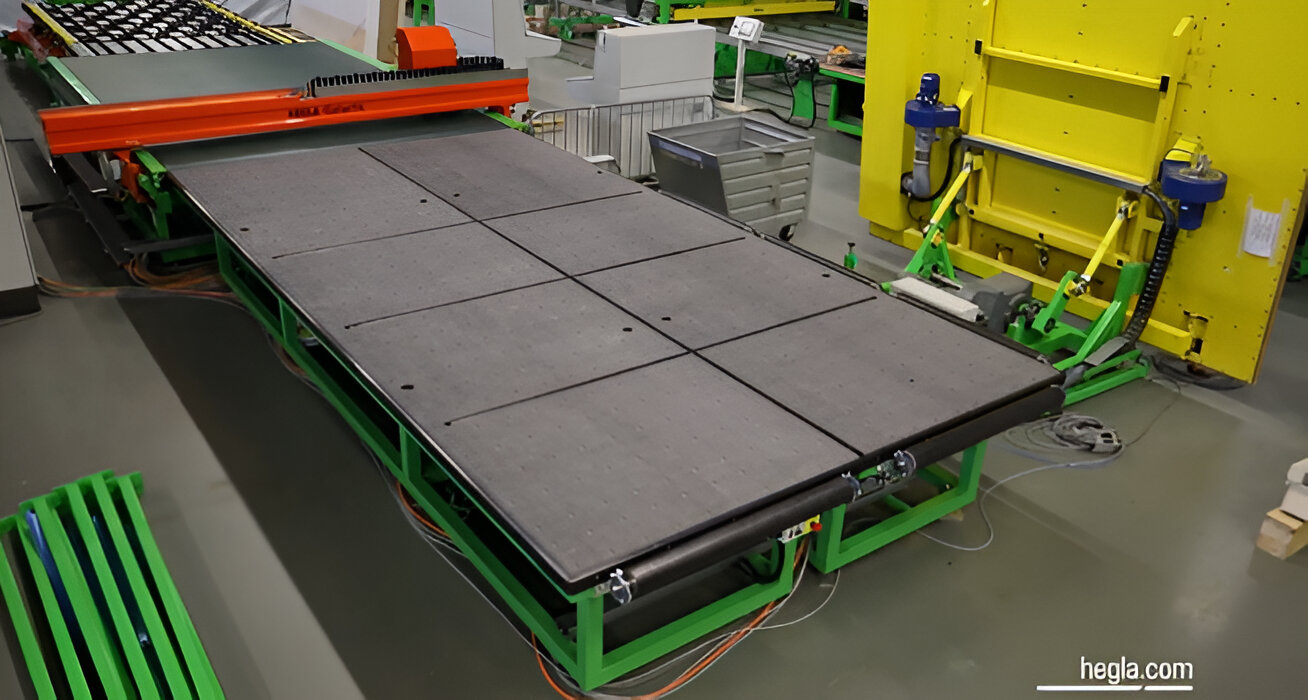

Abandoning traditional roller tables, the Galactic system incorporates a continuous conveyor belt, an essential advancement for handling delicate thin glass. This feature ensures smooth, vibration-free transport across the cutting zone, minimizing microcracks and stress lines that often compromise glass quality. For manufacturers aiming to improve yield and consistency, this seemingly subtle design change marks a major leap forward.

Precision at the Core

HEGLA’s specialized cutting head is engineered to deliver perfect scoring results even at the thinnest tolerances. It adjusts dynamically to the fragility of the substrate, ensuring clean separations with minimal waste. In a field where one flaw can mean a full sheet loss, this level of control translates to serious savings and superior product integrity.

The Future, Delivered

With Galactic, HEGLA doesn’t just offer a machine, it sets a new benchmark in the glass industry. As thin glass applications expand across sectors, this innovation signals HEGLA’s commitment to leading with intelligence, engineering finesse, and industry foresight. The future of thin glass is no longer fragile, it’s Galactic.

Source: HEGLA with additional information added by Glass Balkan