Felbermayer Fenster und Türen Erzeugungs GmbH, based near Vienna, has taken a major step in window manufacturing by investing in a fully automated insulating glass production line from LiSEC. Founded in 1963, Felbermayer employs 195 people across a 22,000 m² production area and is recognized as a pioneer in automated flat glass processing. The company is known for its full-service offering in wood, wood/aluminium, plastic, and plastic/aluminium windows, including EI-90 fire protection models.

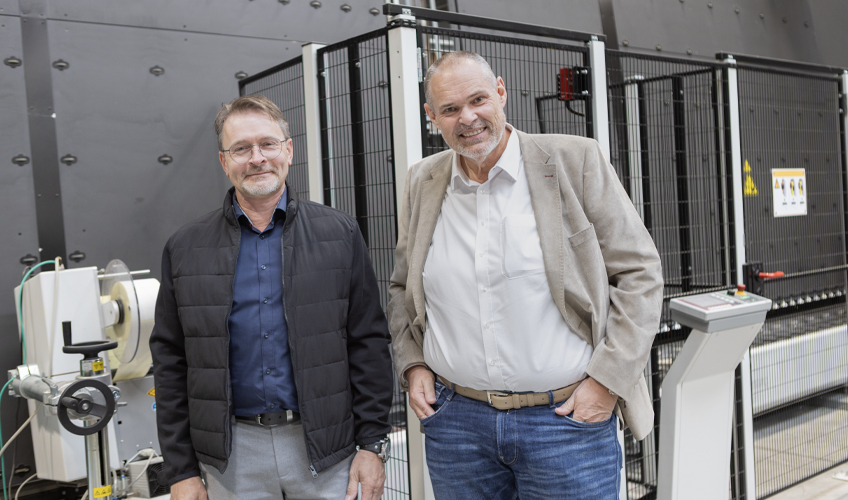

In 2021, managing director Helmut Felbermayer decided to produce insulating glass in-house, making the company one of the few Austrian window manufacturers covering this service range. To implement this, Felbermayer turned to LiSEC, citing its role as one of Austria’s most innovative mechanical engineering companies.

The collaboration resulted in a smooth project rollout, with machines and software delivering fully automated production, from cutting and edge processing to assembly and sealing. Only three employees oversee operations, while manual handling errors and customer complaints have nearly disappeared.

Felbermayer’s facility includes advanced LiSEC equipment such as the VSL-A laminated glass cutting system, ESL-RS float glass cutting system, GPS.perfectscan scanners, and the fully automatic insulating glass line with TPA-A thermoplastic spacer applicator, gas-filling press, cork applicator, and sealing machine. The company also integrates RFID tracking for unique material flow management.

Sustainability remains central, with photovoltaic-powered production and recycling processes in place. Looking ahead, Felbermayer aims to further innovate, focusing on larger glass formats, solar integration, and optimized production efficiency.

Source: LiSEC with additional information added by Glass Balkan