Insulating glass units (IGUs) are critical for modern buildings, but exposure to temperature fluctuations and UV radiation can compromise their performance. Over time, gas leakage reduces thermal insulation, increasing energy demand. A 2016 study by Asphaug, Jelle, Gullbrekken, and Uvsløkk on accelerated aging of double-glazed units emphasizes the need for precise quality assessment tools to prevent energy losses and extend IGU lifespan.

The research found that spacer materials play a key role in durability. IGUs with aluminum spacers lost an average of 7% argon concentration under harsh environmental conditions, directly increasing U-values and heating requirements. Such degradation impacts energy efficiency and long-term operating costs, highlighting the importance of monitoring gas levels throughout the IGU lifecycle.

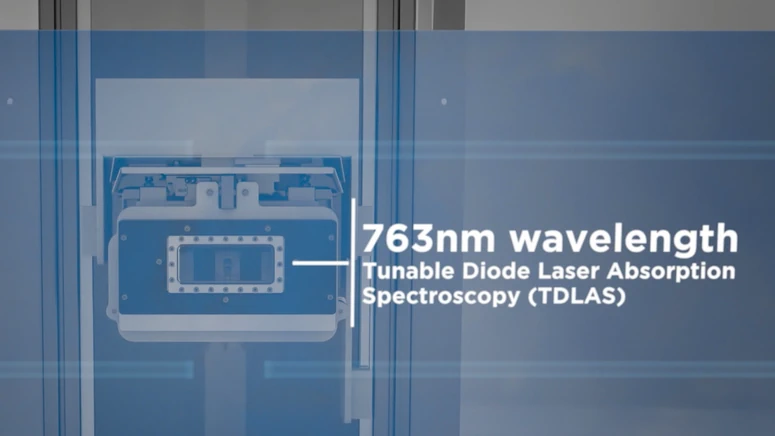

Sparklike devices provide a reliable, non-destructive solution. The Sparklike Handheld measures argon in double-glazed units, while the Sparklike Laser Portable and Integrated models use tunable diode laser absorption spectroscopy (TDLAS) to measure argon and krypton in double and triple glazing. Accuracy is ±2%, validated by ift Rosenheim testing.

These devices allow proactive maintenance, early detection of leaks, and compliance with EN and ASTM standards. They are mobile and versatile, usable on production lines or construction sites, eliminating destructive sampling while ensuring consistent thermal performance.

By integrating Sparklike technology, manufacturers and installers safeguard IGU durability, reduce energy waste, and support sustainable building practices, while protecting both efficiency and brand reputation.

Source: Sparklike with additional information added by Glass Balkan