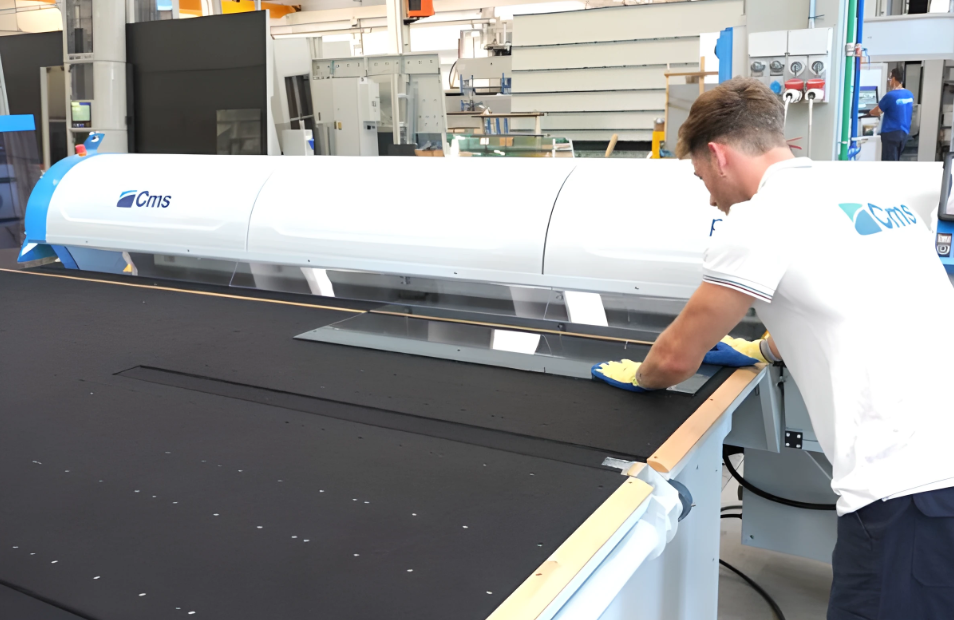

The CMS Proxima is a compact, fully automatic dry horizontal seaming machine tailored for small to medium-sized glassworks seeking efficiency without large investments. Its standout feature is the ability to seam glass edges directly on the cutting table, reducing extra handling and streamlining production. Compatible with both monolithic and laminated glass cutting tables, Proxima also operates in stand-alone mode using a simple support table, making installation straightforward and quick.

Designed for versatility, the machine automatically adapts to different glass lengths and thicknesses, while its dry processing system with dust extraction eliminates water use and sludge disposal, significantly lowering operating costs. Proxima is also ideal for processing low-emissivity (Low-E) coated glass safely, with no need for immediate washing after seaming.

Requiring minimal maintenance, it delivers consistent, high-quality edge finishing. Compact, easy to operate, and cost-effective, CMS Proxima is a practical solution for glassworks aiming to optimize processes, boost productivity, and reduce expenses efficiently.

Source: CMS Glass Technology with additional information added by Glass Balkan