Two phenomena are taking place in parallel on the global stage of flat glass fabrication: on one hand, the number of machines available on the market has grown significantly and, on the other, the companies using them are increasingly experiencing difficulty in finding specialist operators with specific skills. This can lead to inefficiencies that are costly for glass fabrication companies.

To understand if there is a solution to this problem, we spoke to Laura Bonaiti, head of business development and digital products for CMS.

How do you face this scenario?

At CMS we are very attentive to these aspects because our focus has always been on meeting the needs of our customers.

Specifically, since hardware quality is essential, we believe that two aspects make the difference for customers in this scenario: the human-machine interface, and having a partner, not just a supplier.

How does CMS respond to these needs?

CMS is working on four key points: creating the most intuitive and user-friendly machine interfaces ever, adding fabrication process expertise in our software so that the machines guide the operators step by step, and providing our customers with increasing amounts of data on how they carry out the process in order to make it more efficient (for savings and increased productivity). Finally, we are introducing a service paradigm shift from reactive service (acting when we receive a call from a customer) to proactive support, which involves contacting customers even before the problem strikes and stops the machine.

Can you tell us more about how you help CMS customers save money and increase their productivity?

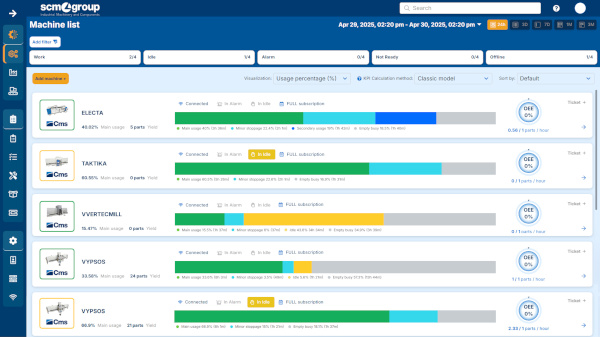

CMS, in collaboration with SCM Group to which it belongs, has created an Internet of Things platform called CMS Connect. It’s a web portal that our customers can access and from which they can monitor their production process efficiency and consumption in real time. This not only means they can optimize the performance of the installed machines, but they can also take targeted action to reduce energy waste and minimize environmental impact. Analyzing the data via the platform allows strategic decisions to be made, improving productivity and prolonging the plant life cycle. In this scenario, CMS is configured as a technological partner, contributing in real terms to the transition towards responsible production models.

Proactive support also seems like a dream. How are you achieving this?

Through a dedicated project, again in collaboration with SCM Group. CMS has developed a service specifically for service departments, called CMS Control Room. It’s a smart system that collects operating data from our machines in real time, and exploits technologies such as machine learning and business intelligence to automatically predict potential critical issues before they occur. Our technicians see which machine is potentially at risk, and can call the customer to prevent the problem.

Can you give us a real example?

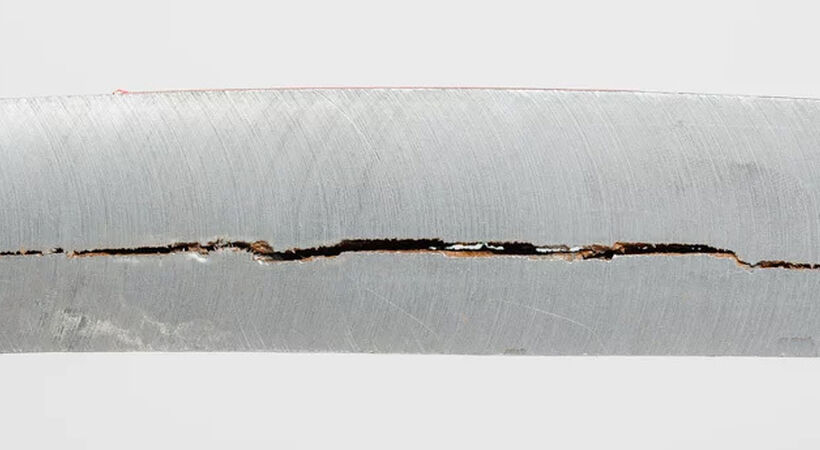

Gladly, through CMS Control Room we receive information about spindle vibration in our installed machines. The software is programmed to distinguish normal vibration modes from abnormal ones. We can even estimate how long until a component will fail based on the vibration it emits.

CMS Control Room informs our technicians that the spindle in a specific machine is vibrating abnormally, and our personnel proactively call the customer to explain the issue and propose a solution before the machine stops.

Really revolutionary! Do you also have other aces up your sleeve for the future?

With the aim of allowing CMS users to solve problems independently, our technicians are also working on developing a Solution Library, a sort of CMS Wikipedia where they can ask, for example, how to import a 3D object. The system automatically answers questions, as well as providing videos and articles.

Given that the digital world is constantly evolving, what is the key to the success of the solutions offered by CMS?

In today’s rapidly changing environment, the key is to adopt an approach based on Design Thinking: a method that combines creativity and strategy, focusing on customers’ actual needs. This allows us to develop digital solutions that are not only technologically innovative, but above all relevant, useful for our customers. Listening to customers, observing the context in which they operate and co-designing with them gives us a continuing competitive advantage.

What are the main challenges in driving digital transformation in a traditionally mechanical sector?

One of the main challenges is to bring together two worlds that have historically spoken different languages: mechanical, based on precision, robustness and reliability, and digital, featuring speed, continuous updates and agile business models.

How important is internal cultural change? And how are you managing it?

Cultural change is the real driver – or brake – of change. It’s not just about introducing new digital products, we need to rethink the way we tackle challenges, make decisions and collaborate within the organization. In a traditionally mechanical sector such as ours, this transition requires a structured change management approach capable of involving people, expertise and processes at all levels. We train our staff through our internal campus, using specialized companies as well as through field support. Investing in personnel training is really key because people are what truly add value to a company.

Source: CMS Glass Technology with additional information added by GlassBalkan