As Tirana undergoes rapid urban transformation, the architectural landscape is becoming more ambitious, with taller buildings, tighter timelines, and increasingly complex façade geometries. To stay ahead of these demands, ALCA has expanded its production capabilities with the installation of a new vertical CNC machining center from Muratori Machines.

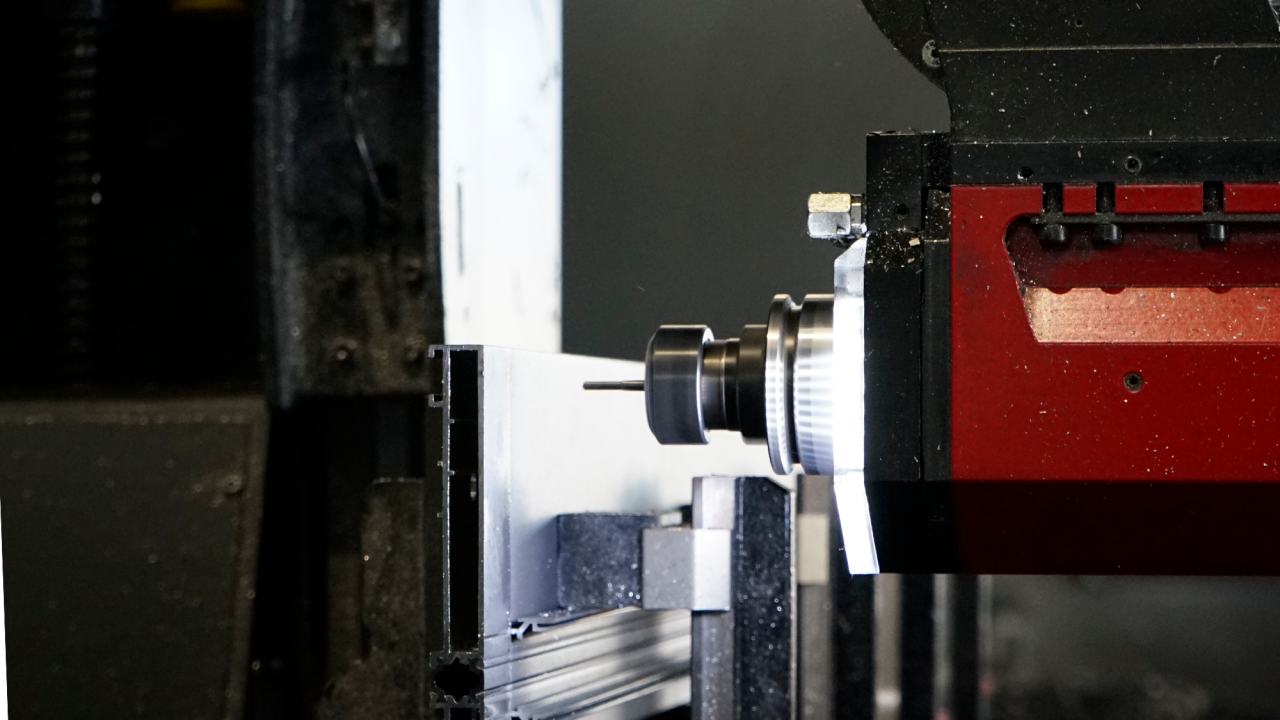

This advanced machine is specifically designed for high-speed, high-precision processing of aluminium composite panels. Its vertical layout not only optimizes floor space but also improves chip removal and enhances operator safety and workflow efficiency, critical factors in a fast-paced production environment.

The new line is further supported by two dedicated post-processing machines for bending, folding, and shaping façade panels with consistency and accuracy. Together, these systems offer ALCA complete in-house control over the entire lifecycle of panel production, from raw material to final assembly.

This strategic investment complements ALCA’s two existing Emmegi CNC machining centers, creating a fully integrated and flexible production setup. The result is a dramatic improvement in speed, precision, and responsiveness.

With these capabilities, ALCA can now meet more complex design challenges, reduce lead times, and minimize errors caused by fragmented workflows. Most importantly, it allows for greater design freedom, giving architects and developers the confidence that their visions can be executed exactly as planned.

This isn’t just about new machinery, it’s about reinforcing ALCA’s role as a key enabler of Tirana’s architectural future through innovation, quality, and control.

Source: Alca with additional information added by Glass Balkan