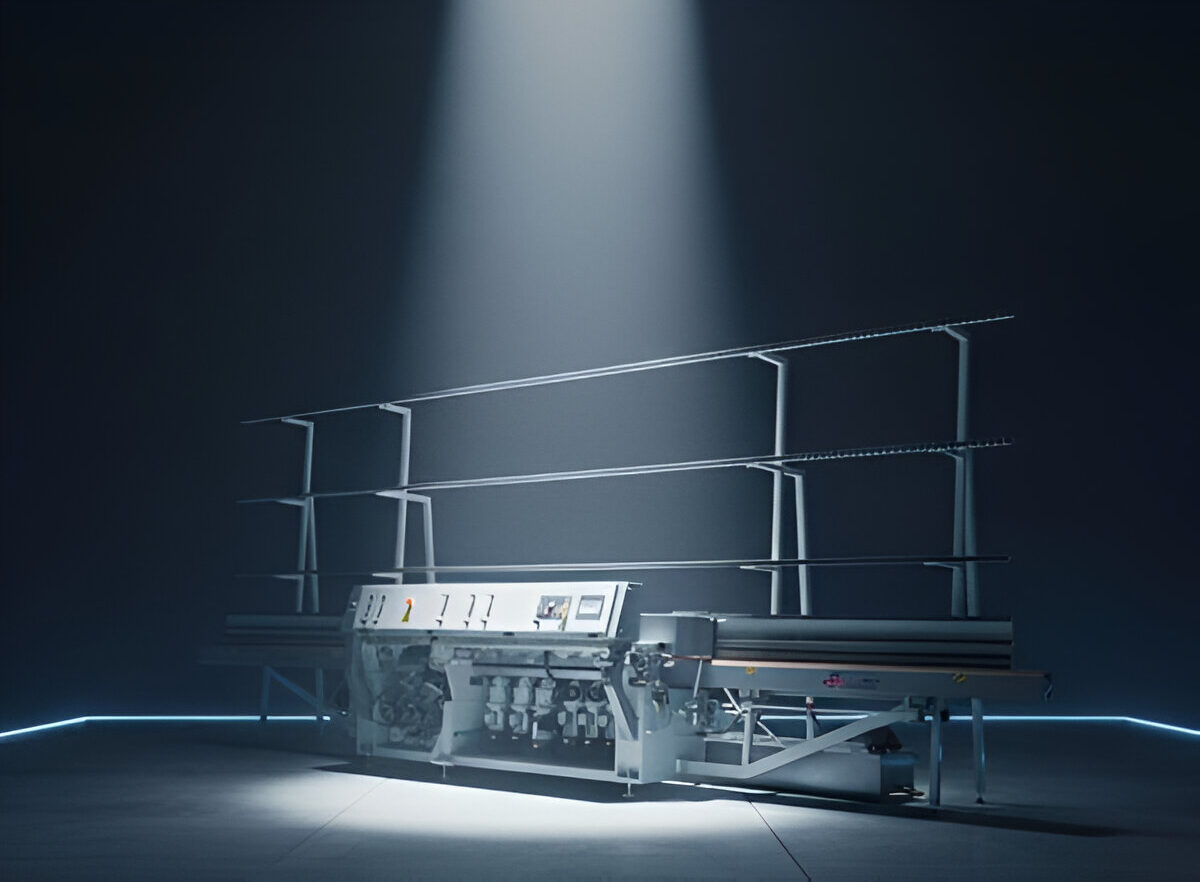

For over half a century, Schiatti Angelo Srl has set benchmarks in glass machinery innovation, and the SME10 continues that tradition with a new standard in straight line edging. The machine features a revolutionary conveyor system where rubberized pads equipped with ball bearings move along a tempered steel guide. This configuration cuts friction by up to 80% compared to traditional setups, virtually eliminating vibration and guaranteeing precise, smooth finishes from 0° to 45°, including perfect cerium oxide polishing on both flat edges and arrises.

The SME10’s touch-screen PLC interface gives operators full digital control, allowing adjustments to glass thickness, speed, and tilt while displaying live operational data. A built-in predictive diagnostic system tracks vibrations and pressure levels, identifying potential issues early and reducing maintenance time by half. Its independently adjustable diamond wheels and automatic polishing wheels ensure exact power calibration and reduced manual handling.

With a total power consumption of just 17.7 kW, the SME10 offers remarkable energy efficiency, supported by a closed-loop water cooling system that prevents waste and enhances sustainability. Thanks to its modular construction, it can be customized with various optional features to meet specific production demands, combining reliability, performance, and environmental responsibility in one machine.

Source: Schiatti Angelo Srl with additional information added by Glass Balkan