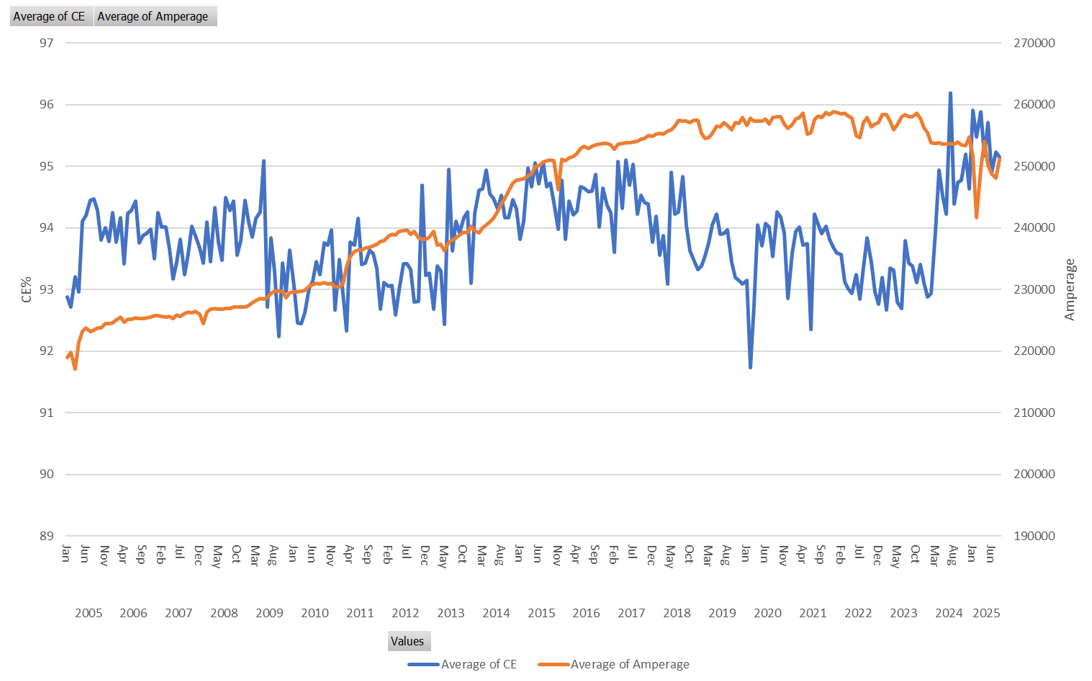

Tomago Aluminium, located in Tomago, New South Wales, Australia, has set a global benchmark in Current Efficiency (CE%), achieving sustained levels above 95% for its AP18 aluminium smelting cells. This represents the highest CE% in the company’s history and a TAC record since the introduction of AP22 (220,000 amps) in the smelter. The achievement reflects two decades of operational data (2005–2025), continuous process improvement, and a strong team culture focused on excellence.

Grant Farrow, Process Superintendent – Electrolysis, said: “Achieving this sustained level of performance is incredibly rare and sets a new Tomago standard.” The record was driven by three main factors:

- Improved Anode Quality – stricter specifications and testing reduced anode variability by 15%, directly boosting CE%.

- Stronger Work Quality Standards – consistent training and procedural discipline across three daily shifts enhanced cell stability.

- LMO Process Team’s Continuous Improvement – precise bath chemistry control, reduced anode effects, and optimized feeding schedules stabilized pots and increased energy efficiency.

Enhanced manufacturing standards and tighter quality control reduced operational variability, while ownership of performance at every level ensured sustained excellence. Tomago Aluminium plans to refine its operational “sweet spot,” targeting even higher CE% and energy efficiency in the coming years.

Source: Tomago Aluminium with additional information added by Glass Balkan