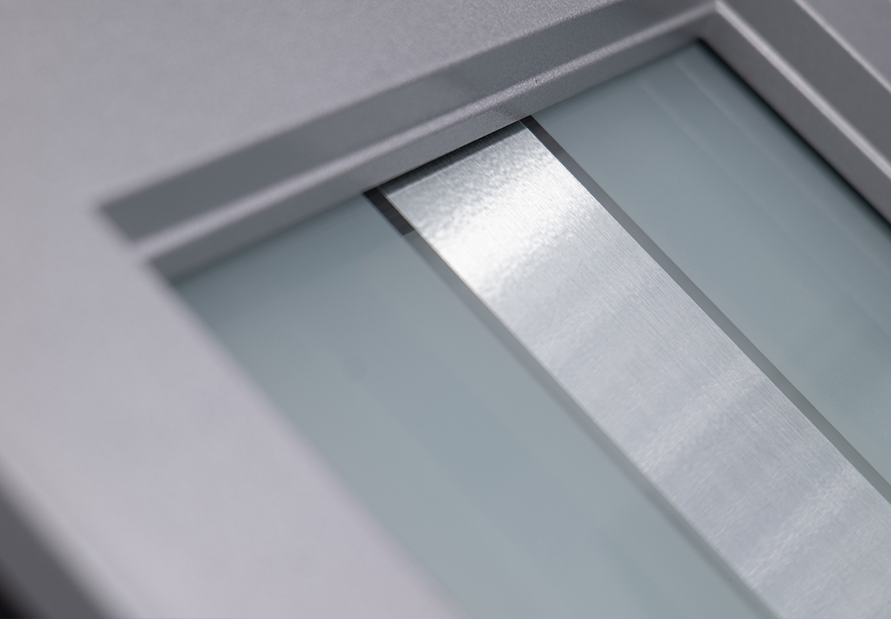

DoorCo reports that 98% of all doors glazed through its in-house preparation service now use the company’s own Flip cassette system, with just 2% accounted for by the metallic-finished Inox range.

Developed by Strategy Director Mark Towers and launched in 2021, the Flip system was designed to replace traditional glazing tape with a pre-foamed gasket. This innovation improves installation speed and enhances performance, achieving BS6375-2015 and EN1027 standards for weatherproofing and security. Available in three profiles and the full DoorCo colour and stain range, Flip has quickly become the default choice across the company’s prepped door portfolio.

Operationally, the benefits are clear. According to Glazing Cell Manager Kayley Woods, a twin vertical door can be glazed in just seven minutes using Flip, more than 50% faster than with traditional tape. Its detachable and reglazable design reduces error rates while enabling more effective team training within the glazing cell.

Since launching its in-house glazing service seven years ago, DoorCo has focused on delivering doors prepped to near-completion. The dominance of Flip has allowed the company to streamline production, maintain consistent lead times, and strengthen its reputation as an innovator in the fenestration sector.

Source: trade.door-co with additional information added by Glass Balkan