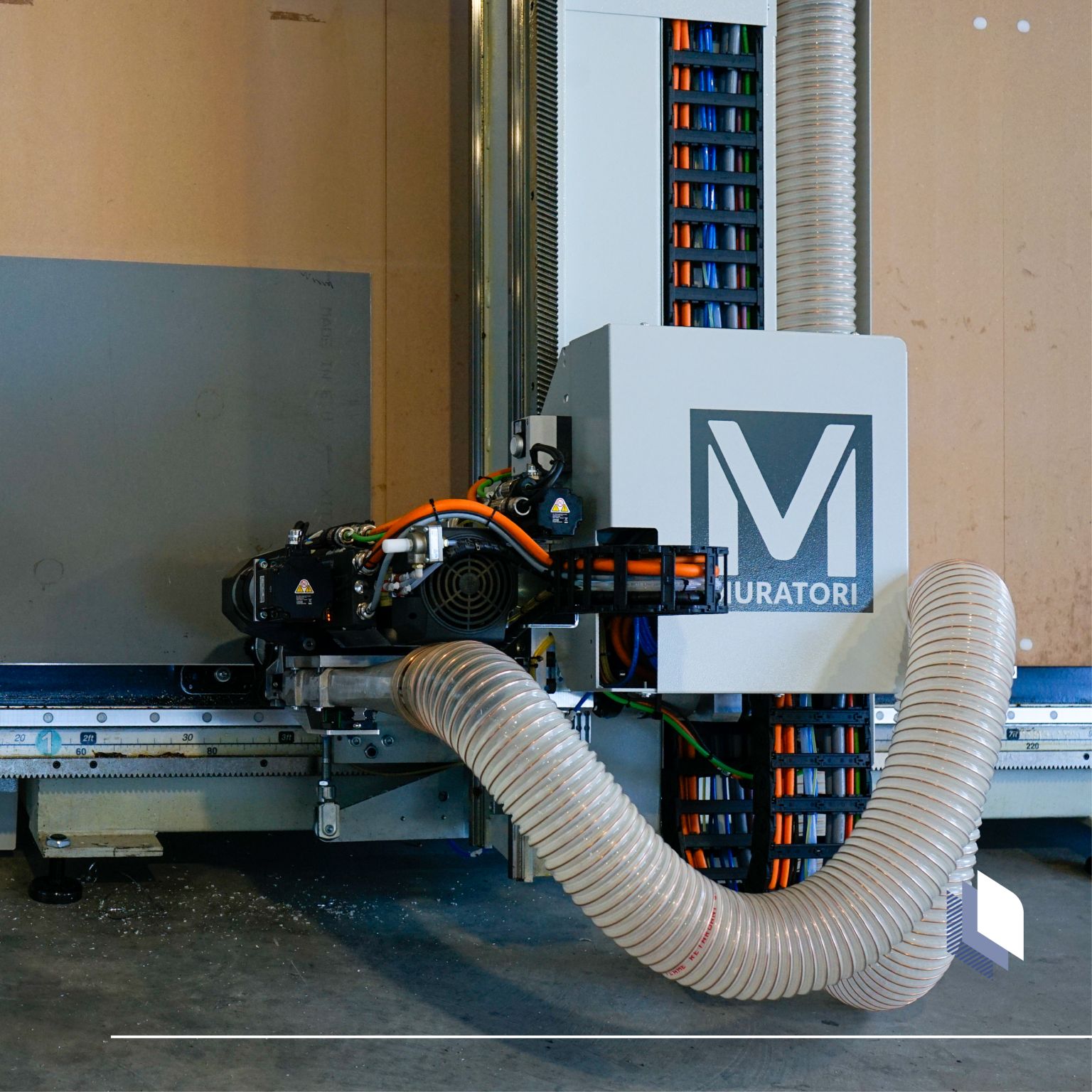

The new vertical CNC machining centre from Muratori Machines has been successfully integrated and is now fully operational at ALCA’s factory. This equipment, designed for high-precision processing of aluminium composite panels, features a vertical layout that optimizes floor space, improves chip removal for cleaner cuts, and enhances operator safety and workflow efficiency.

Supported by two dedicated post-processing machines for bending, folding, and shaping, the setup provides ALCA with end-to-end control over the entire panel lifecycle, ensuring accuracy and consistency throughout production.

This installation complements ALCA’s existing CNC machining centres by Emmegi, creating a flexible and comprehensive in-house capability capable of handling a wide range of façade types, from glazed curtain walls to complex ventilated cladding systems.

The partnership between ALCA and Muratori Machines brings together ALCA’s commitment to high-quality façade manufacturing with Muratori’s advanced CNC technology. This collaboration enhances ALCA’s production efficiency and precision, enabling the company to meet complex architectural demands with reliable and innovative solutions.

Source: ALCA with additional information added by Glass Balkan