Edgetech, part of Quanex, has teamed up with Italian machinery specialist Forel to introduce a significant advancement in triple glazing – an automated production line for thin triple insulating glass units (IGUs).

These thin triples deliver the thermal performance of standard triple glazing but with reduced weight, lower costs, and simpler manufacturing. Central to the development is Edgetech’s flexible warm-edge Super Spacer, which allows the middle pane to be positioned with sub-millimetre accuracy, ensuring both durability and energy efficiency. This precision makes it possible to use centre panes as slim as 1 mm without compromising performance.

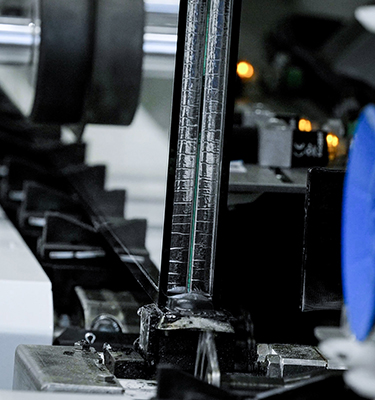

The partnership began 18 months ago when Quanex approached Forel to explore a new way of encapsulating the central thin pane in a sealed unit. Unlike traditional triple glazing, which requires double sealing, this design uses a single outer seal similar to double glazing. Forel adapted its High Speed Line to produce thin triples that fit into existing 70 mm window systems, allowing manufacturers and installers to continue using their current processes.

Tony Palmer, Head of Sales at Edgetech, said triple glazing is vital for meeting future energy standards and growing market demand, but uptake in the UK has been limited by manufacturing constraints. “We saw the adaptability of Super Spacer as the key to making thin triples viable,” he explained.

Brian McDonald, CEO of Forel UK & Ireland, praised Edgetech’s forward-thinking approach. The first UK thin triple production line is set to start operating by the end of 2025, representing a milestone in delivering lightweight, high-performance glazing to the market.

Source: Edgetech with additional information added by Glass Balkan