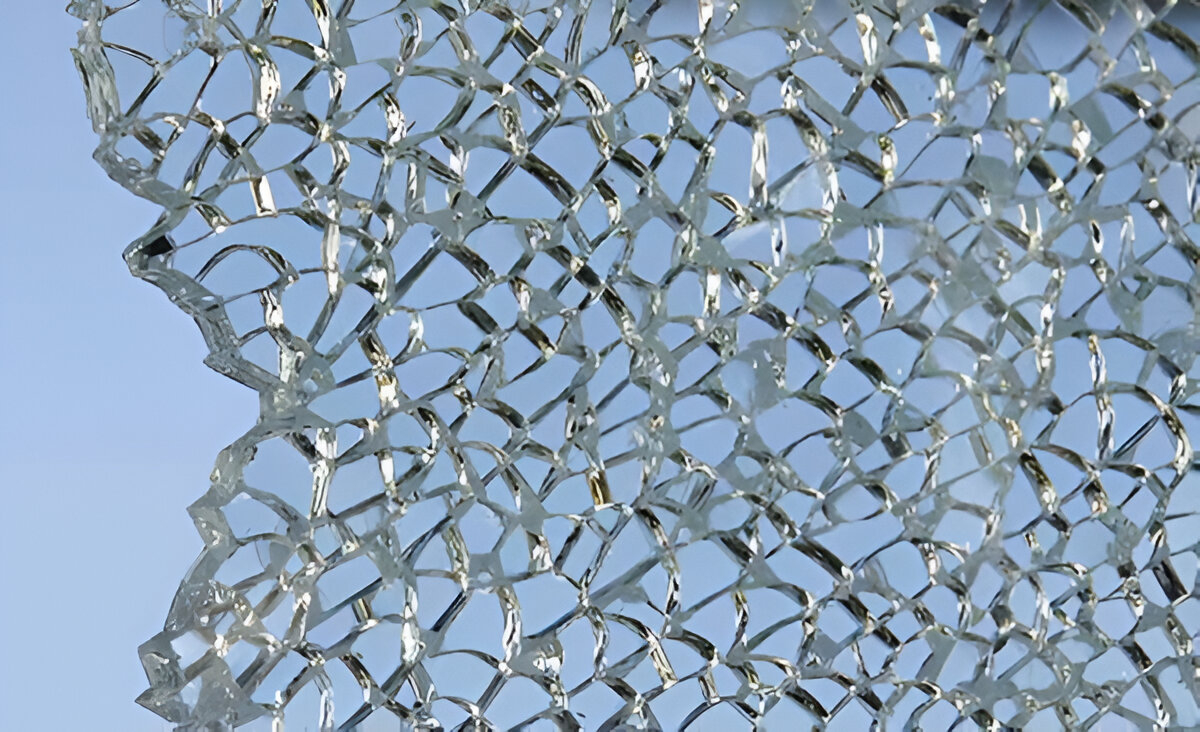

In an era demanding both security and sustainability, laminated safety glass (LSG) is gaining renewed attention, not just for its strength, but now also for its recyclability. Traditionally difficult to recycle due to its tightly bonded polymer interlayers (usually PVB), LSG has long been a sustainability challenge in the glass industry. But that’s beginning to change.

At the CircuClarity One conference, held during glasstec 2024 in Düsseldorf, researchers from the Technical University of Darmstadt unveiled a promising method for separating LSG into reusable components. Led by Dr Miriam Schuster and Prof Dr Johannes Kuntsche, the team presented a four-stage process that enables clean separation of the glass and PVB layers, without glass breakage or material contamination.

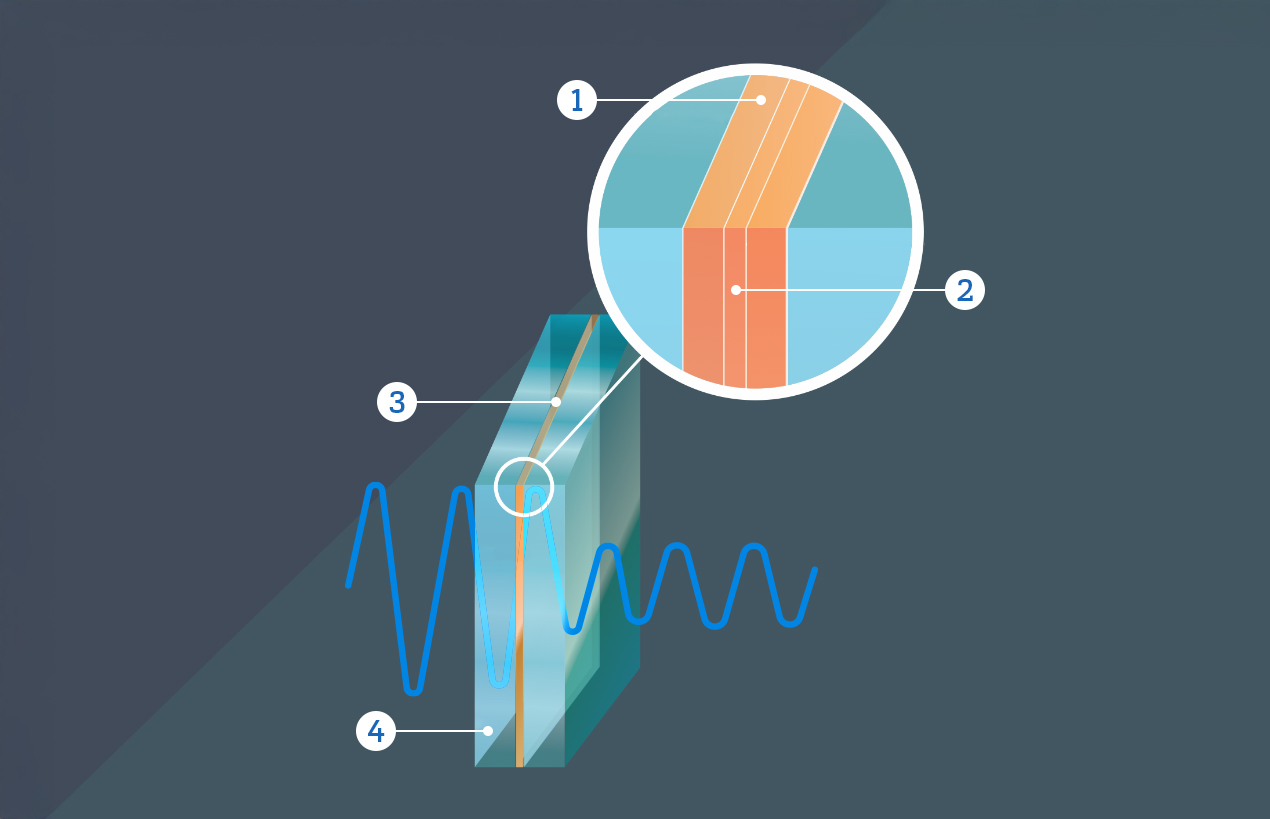

The technique involves:

- Heating the glass to induce the “daisy effect” in the PVB,

- Mechanical separation of the glass layers,

- Water-assisted treatment, and

- Peeling the residual film from the surface.

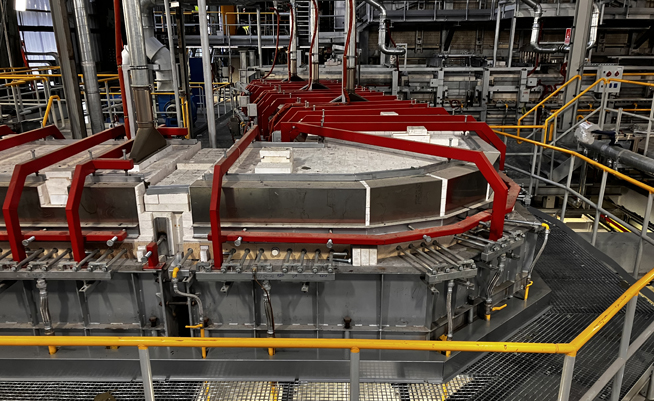

Tests on different interlayer types, adhesion strengths, and moisture levels yielded encouraging results. The ultimate goal is closed-loop recycling: reintroducing the recovered glass into float glass production or reusing it directly in secondary applications.

The project addresses a critical obstacle in modern glass architecture and moves the industry closer to genuine circularity. A follow-up event, CircuClarity Two, is already planned for glasstec 2026, continuing momentum in making high-performance glass not only safer, but also greener.

As Dr. Schuster notes, “We’re not just protecting buildings anymore, we’re protecting the future.”

Source: glasstec with additional information added by Glass Balkan