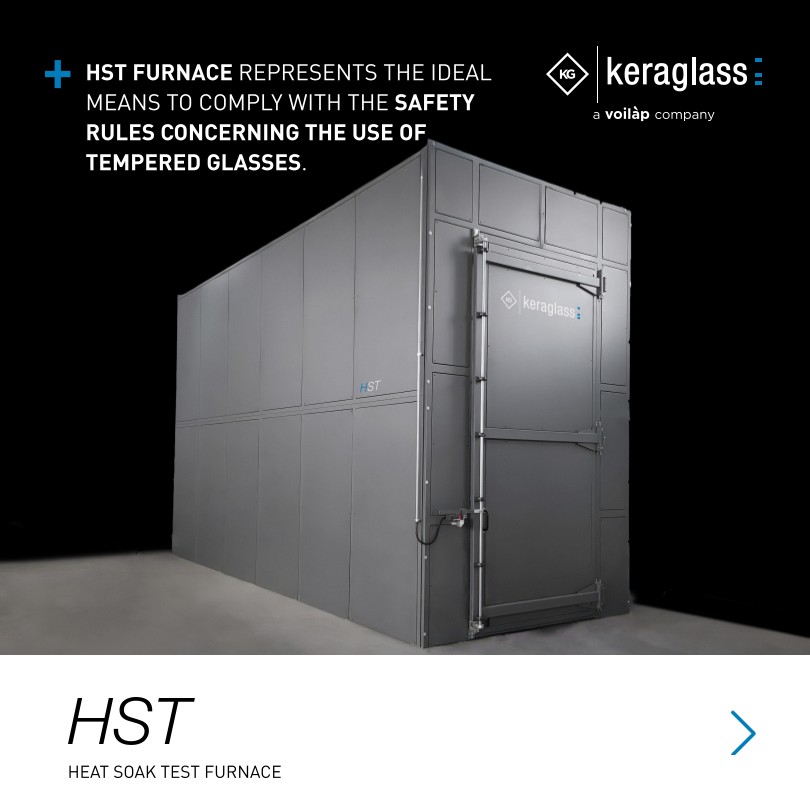

Spontaneous breakage of tempered glass, often caused by nickel sulphide (NiS) inclusions, has long been a challenge for glass manufacturers and end-users alike. Addressing this issue head-on, Keraglass introduces its Heat Soak Test Furnace, a cutting-edge solution designed to virtually eliminate unexpected glass breakage and ensure maximum safety.

The Heat Soak Test Furnace subjects tempered glass to a controlled high-temperature process, accelerating the detection of nickel sulphide defects that could otherwise cause spontaneous breakage later in the glass’s lifecycle. This rigorous testing guarantees that only the safest, most reliable glass reaches the market, providing peace of mind for manufacturers, architects, and consumers.

Certified according to the stringent DIN EN 14179-1 standard, Keraglass’s furnace adheres to industry-leading requirements, validating the highest level of product quality and safety. The furnace’s high-temperature environment simulates long-term stress in a short timeframe, ensuring that any defective glass breaks during testing rather than in actual use.

By relying on Keraglass technology, customers are assured of a certified product that protects end-users from the dangers and costs associated with spontaneous tempered glass failure. Keraglass’s commitment to innovation and safety delivers trusted, superior glass solutions that elevate industry standards.

Source: Keraglass with additional information added by Glass Balkan