Signature Hiller GmbH, a German leader in traffic signage and transport solutions, sought to improve internal production to stay competitive. The company aimed to reduce outsourcing and increase efficiency when working with materials like aluminium, composite panels, and plexiglass.

A Custom CNC Fit for Limited Space

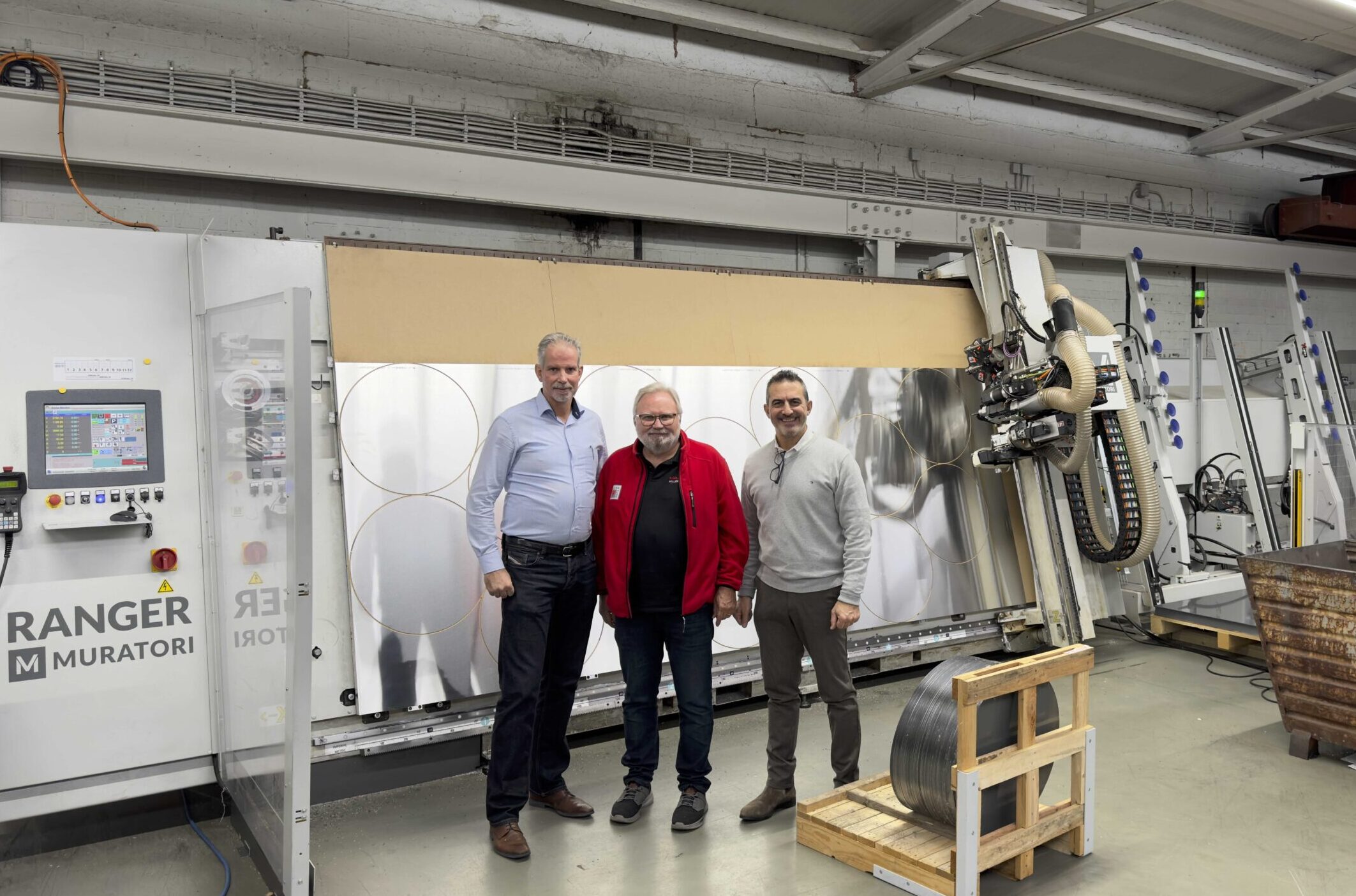

To achieve this, Signature Hiller implemented the Ranger CNC Work Center from Muratori Machines. The machine’s vertical design was a key advantage, customized to fit the company’s space constraints while enabling large-format machining previously outsourced.

Tangible Results in Cost and Time

The benefits were clear. By using advanced nesting techniques, Signature reduced material waste by 8–10%. Handling large sheets in-house significantly cut production times and lowered external processing and logistics costs.

Streamlined Operation with Minimal Labor

The Ranger CNC is easy to operate and requires only one person, further reducing labor costs. This improved workflow efficiency and freed up staff resources to focus on other tasks, increasing the company’s overall agility.

Strategic Partnership and Long-Term Impact

The collaboration with Muratori Machines proved highly effective. With greater independence, faster turnaround, and reduced operational costs, Signature Hiller is now better positioned to meet evolving market demands with confidence.

Source: Muratori with additional information added by Glass Balkan