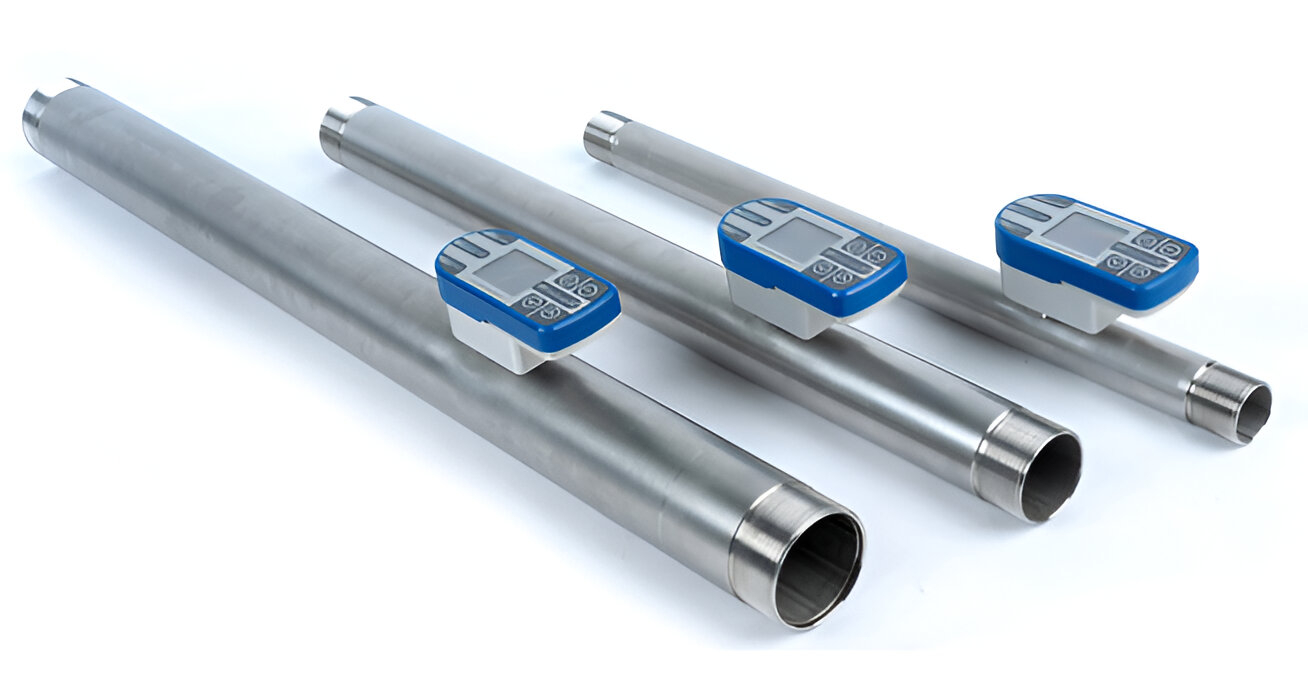

VPInstruments, a global leader in industrial energy monitoring, has introduced the VPFlowScope® M Thermal In-line, a compact and advanced flowmeter that sets new standards for compressed air and industrial gas measurement. This 4-in-1 device measures bi-directional flow, pressure, temperature, and total flow, providing complete insight into energy consumption directly at the point of use.

Designed for Point-of-Use Efficiency

Optimised for smaller diameters (1 to 2 inches), the VPFlowScope M Thermal In-line is ideal for submetering and point-of-use applications. It enables accurate monitoring of energy usage, helping industries reduce waste, improve efficiency, and optimise their operations.

Smart Maintenance with VPSensorCartridge®

At the core of the device is the patented VPSensorCartridge® technology, which allows users to replace the sensor cartridge on-site. This eliminates the need for traditional recalibration, significantly reducing maintenance time and costs while ensuring consistent, reliable measurements without disrupting operations.

Flexible Installation and Seamless Integration

The device features Quick Connect technology for simple and safe installation, ensuring precise alignment every time. Connectivity options include 4-20mA/Modbus RTU or Power over Ethernet (Modbus TCP), allowing seamless integration into various systems and environments.

Lowest Total Cost of Ownership

By combining advanced measurement capabilities with low maintenance and flexible installation, the VPFlowScope M Thermal In-line offers the lowest total cost of ownership. With near-zero downtime, lower transport costs, and long-term reliability, it represents a smart investment for manufacturers aiming to control and optimise their compressed air and gas systems.

Source: VPInstruments with additional information added by Glass Balkan