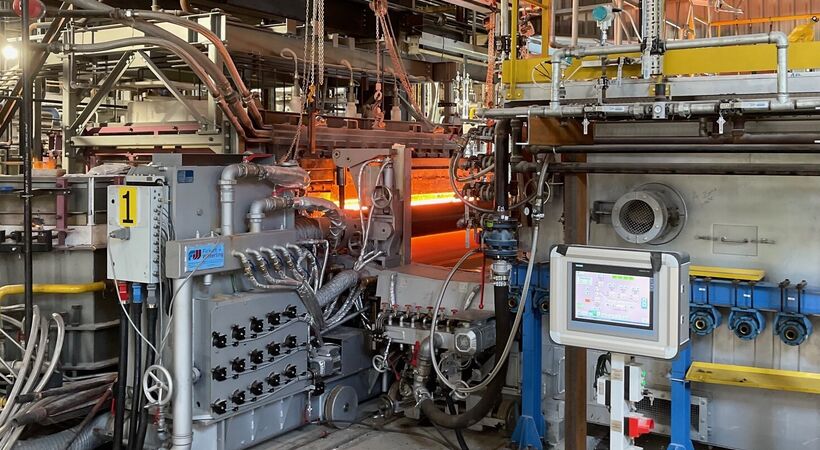

Pilkington UK has inaugurated a state-of-the-art rolled glass production line at its historic Greengate Works site in St Helens, marking a major milestone in British glass manufacturing. The project involved a remarkable technical feat, engineers had to breach the side of a live float glass furnace to construct a specialized canal that diverts molten glass to the new line located in an adjacent building. This bold approach enables both float and rolled glass production from a single furnace, a shift that significantly boosts operational efficiency and reduces environmental impact.

Reviving Texture by Pilkington

The new line is dedicated to manufacturing the company’s “Texture by Pilkington” range, a curated collection of 21 patterned and decorative glass designs. Popular in interior architecture, this range balances privacy and aesthetic appeal, catering to designers, specifiers, and homeowners alike. By relocating this production from the nearby Watson Street Works, which ceased operations after two centuries, Pilkington UK centralizes its manufacturing processes at Greengate Works.

Sustainability at the Core

This move is more than a logistical upgrade, it’s a cornerstone of Pilkington UK’s sustainability strategy. Consolidating glass production to a single furnace cuts 15,000 tonnes of CO₂e annually, the equivalent of removing over 8,800 cars from the roads each year. It’s a tangible step toward the company’s ambitious climate targets: a 30% emissions reduction by 2030 and net zero by 2050.

Government-Backed Green Innovation

This transformation was supported by a £3.7 million grant from the UK government’s Industrial Energy Transformation Fund (IETF), which backs industrial decarbonisation initiatives. The funding affirms Pilkington UK’s role not just as a legacy manufacturer but as a pioneer in the future of low-carbon glassmaking.

Source: Pilkington UK with additional information added by Glass Balkan