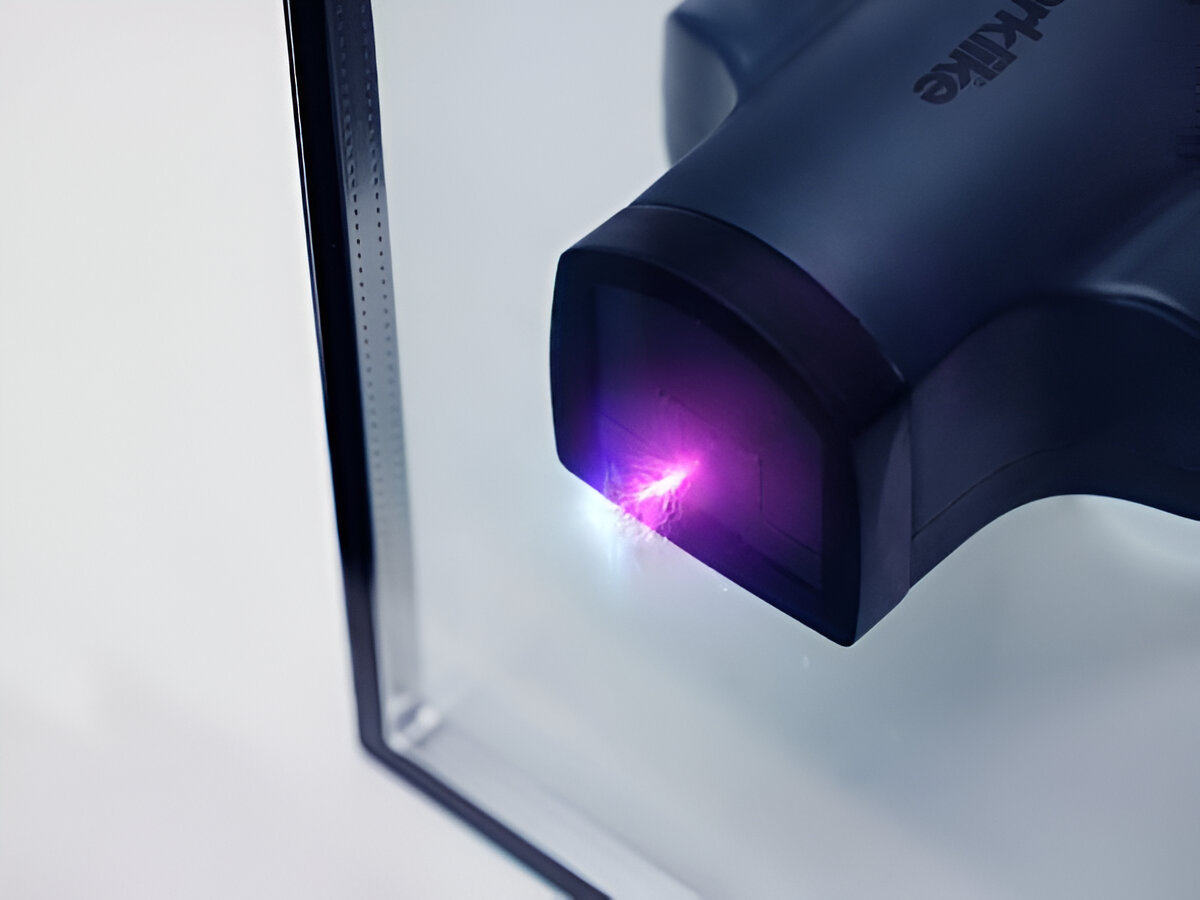

In today’s evolving glass and architectural materials industry, precision and performance are non-negotiable. The synergy between CEL Components s.r.l. and Muratori Machines showcases how strategic partnerships can redefine fabrication standards, particularly in high-performance panel applications.

CEL Components: Lightweight Strength Redefined

CEL Components has established itself as a leader in honeycomb sandwich panels and HPL composites, known for delivering an outstanding strength-to-weight ratio. These honeycomb structures offer unmatched rigidity while remaining lightweight, an ideal solution for demanding architectural applications such as ventilated facades, furniture, bathroom cladding, and custom fabrication.

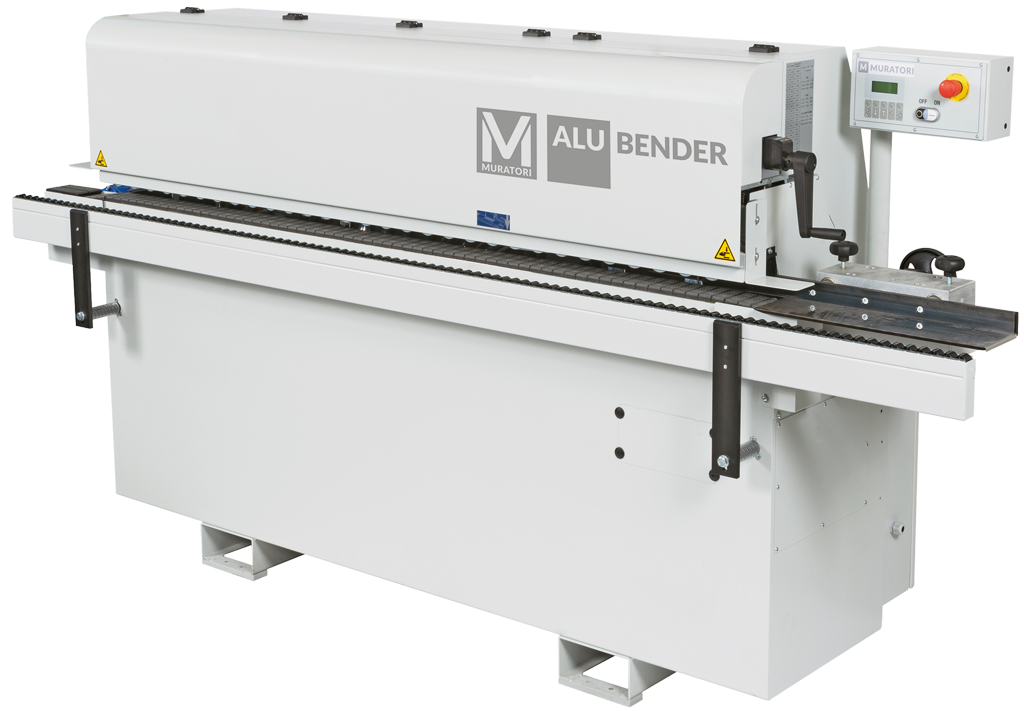

Muratori Machines: Edge Processing Perfection

To match CEL’s panel technology, Muratori Machines provides cutting-edge edge processing systems that ensure clean, precise finishes across a broad range of materials. From solid aluminium (2mm and 3mm) and PVC foam to HPL, fibre cement, and ACM, Muratori’s technology offers reliable performance that enhances both durability and aesthetic appeal.

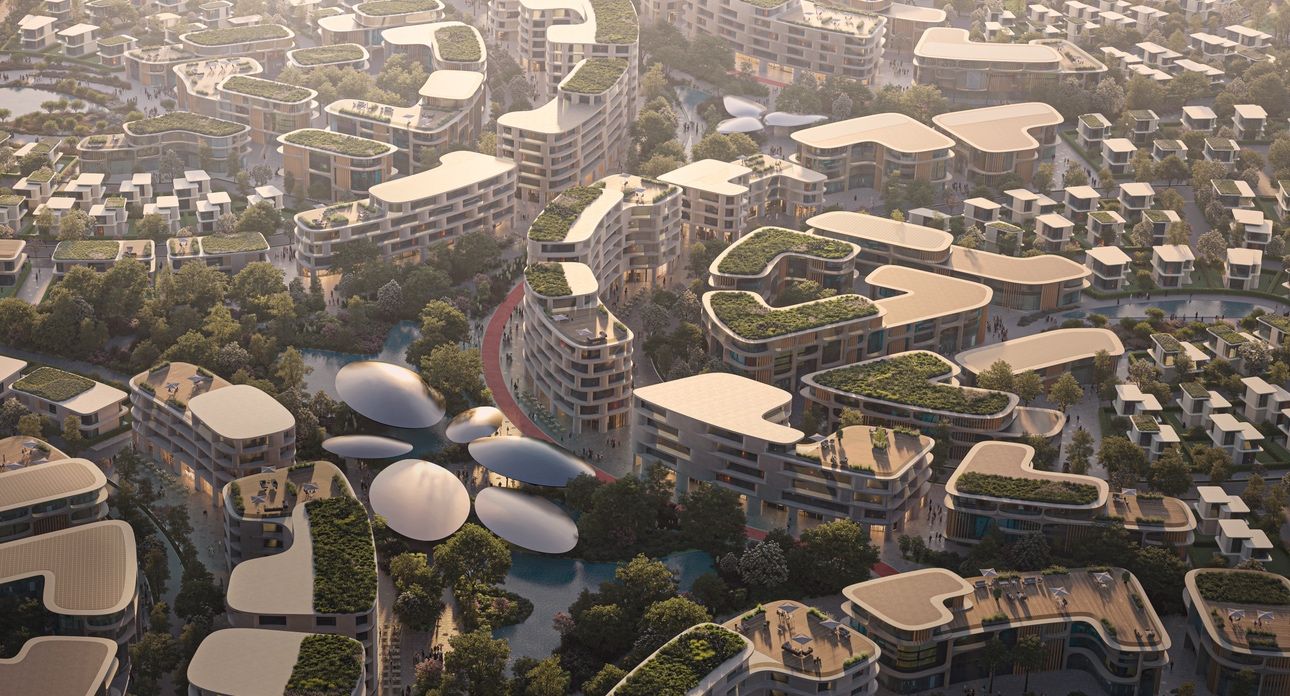

A Complete Solution for Architects and Fabricators

This combination doesn’t just deliver strong, beautiful panels, it offers a holistic solution that reduces material waste and improves operational efficiency. The partnership allows for versatile material handling and supports intricate designs without compromising structural integrity.

Setting a New Standard in Architectural Fabrication

As the demand for lightweight, durable, and visually refined materials grows across the architectural and interior design sectors, the collaboration between CEL Components and Muratori Machines offers a future-ready solution.

Source: PCS Ltd with additional information added by Glass Balkan