A Breakthrough for the Hydrogen Economy

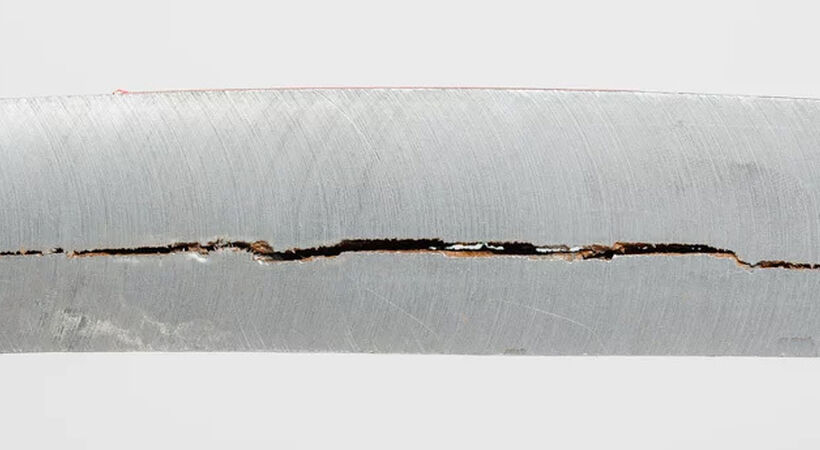

The burgeoning hydrogen economy, a cornerstone of our sustainable future, hinges on the development of robust and reliable materials. While aluminum alloys offer immense promise due to their light weight and corrosion resistance, their susceptibility to hydrogen embrittlement – a phenomenon leading to cracking and failure – has been a significant hurdle. Now, a groundbreaking development by a research team from the Max Planck Institute for Sustainable Materials in Germany, in collaboration with partners from China and Japan, offers a transformative solution.

This international team has engineered scalable aluminum alloys that not only overcome the challenge of hydrogen embrittlement but also boast significantly enhanced strength. Their innovative approach involves the precise incorporation of scandium into aluminum alloys, resulting in a remarkable 40% increase in strength and a five-fold improvement in resistance to hydrogen embrittlement, all while preserving crucial ductility.

At the core of this advancement lies a sophisticated, size-sieved precipitation strategy applied to scandium-added aluminum-magnesium alloys. As Baptiste Gault, group leader at the Max Planck Institute for Sustainable Materials, explains, “Our new design strategy solves this typical trade-off. We no longer have to choose between high strength and hydrogen resistance – this alloy delivers both.” This statement underscores the significance of their work, as it addresses a fundamental compromise previously faced by material scientists.

Beyond the impressive performance metrics, the research team has successfully demonstrated the industrial viability of their new alloys. The strong and hydrogen-resistant materials have been produced under near-industrial conditions, utilizing methods such as water-cooled copper mold casting and thermomechanical processing, which are fully compatible with current industry standards. This crucial step validates the scalability of their innovation, paving the way for widespread adoption in various hydrogen-related applications.

This collaborative effort, primarily involving researchers from Xi’an Jiaotong University, Shanghai Jiao Tong University, and the Max Planck Institute for Sustainable Materials, has been published in the prestigious journal Nature. Their findings lay a critical foundation for the creation of new aluminum materials specifically engineered for the demanding requirements of a hydrogen-powered future. This breakthrough signifies a major leap forward, promising safer, stronger, and more efficient aluminum components that are ready for industrial deployment in the hydrogen economy.

Source: Max Planck Institute for Sustainable Materials with additional information added by GlassBalkan

![[Powered by Freepik]](https://glassbalkan.com/wp-content/uploads/2025/06/low-angle-view-office-building.jpg)