Forel S.p.A., the Italian innovator in glass processing machinery, has introduced a revolutionary production solution for triple‑glazed insulating glass units (IGUs) featuring ultra‑thin centre panes and a flexible spacer. This system addresses the growing market demand for high‑performance glazing that combines superior thermal and acoustic insulation with reduced weight.

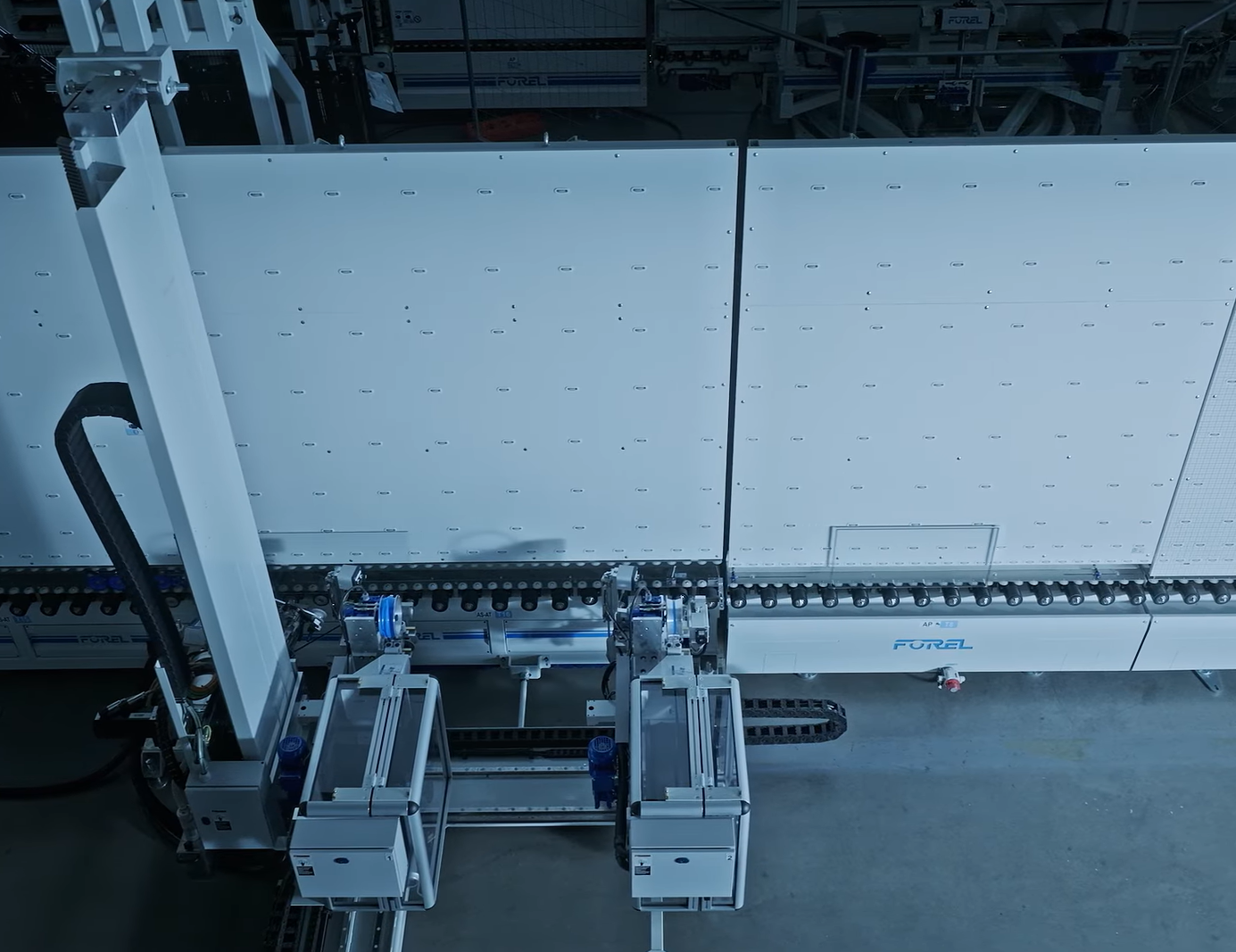

At the core of the innovation is a fully automated flexible spacer applicator with an automatic reel changeover and a final corner closing device. These features ensure precise spacer placement while maintaining high production speeds. A dedicated coupling press assembles the triple unit in a single cavity, allowing the sealing robot to complete the IGU in one pass. This process supports ultra‑thin glass sheets, down to approximately 1 mm, without compromising structural integrity.

Additional software-enabled functionalities include automatic muntin/Georgian bar slit incision, facilitating grid mounting, and the ability to process various glass shapes, offering manufacturers greater design flexibility. Despite being a triple-glass unit, the “thin triple” configuration maintains almost the same overall dimensions and weight as conventional double glazing, allowing easy integration into existing window frames and hardware.

Forel’s innovation not only enhances production efficiency but also provides architects, fabricators, and homeowners with a high-performance glazing solution suitable for both residential new builds and replacement projects.

Source: Forel with additional information added by Glass Balkan